Automotive

- Home >

- Applications >

- Automotive >

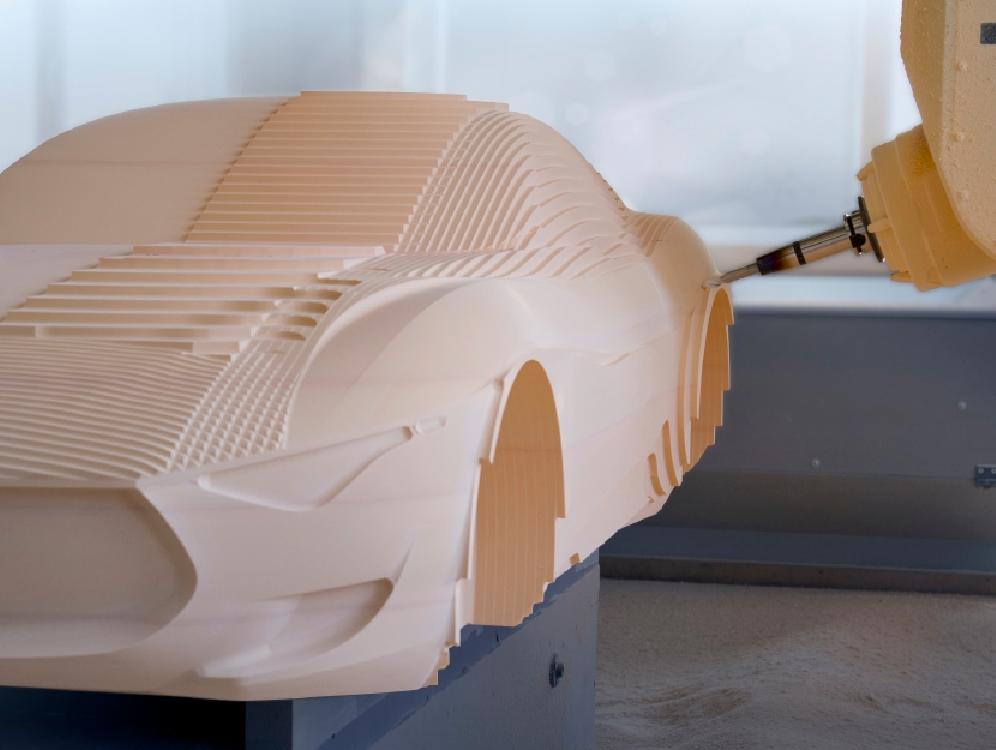

The automotive industry uses thermoset polyurethanes for prototypes and initial parts to reap the benefits of lightweight with excellent durability. Advanced polyurethanes are tough enough for use in high-heat, under-hood applications, “A” and “B” pillar prototyping, automotive interior components, exterior fascias and claddings, grilles, headlight bezels and aftermarket parts.

Not finding what you’re looking for?

Please get in touch with our expert support team to answer all of your questions and recommend a product that best suits your application requirements.

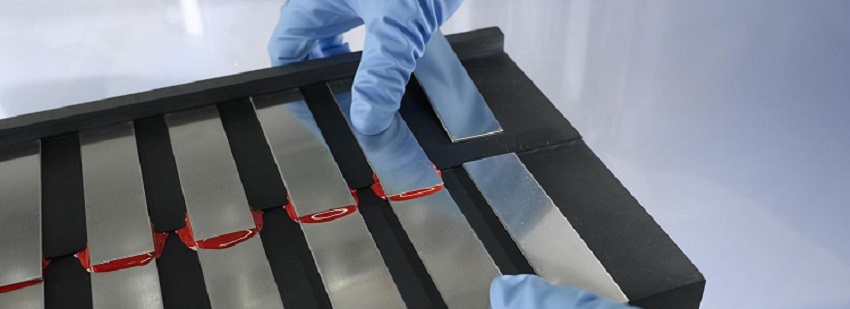

Polyurethane elastomers produce gaskets and seals, padding and wire harnesses. Water clear polyurethanes exhibit outstanding clarity for molding lenses, pillow optics and tail lights. Polyurethane foams are used to absorb energy and sound and are installed under instrument panel surface skins.

Throughout today’s vehicles, polyurethanes, including advanced products from Innovative Polymers, are supporting the manufacture and marketing of new automobile designs and the ultimate production of safer, quieter, longer-lasting components.

Innovative Polymers manufactures many different polyurethanes for automotive applications. Among the products most frequently chosen by automotive companies and their suppliers are:

Gel times from 10 to 25 minutes. The product line includes clear systems as well as cream, off-white and amber colored products. Polymers exhibit good tear strength for automotive interior padding and are tough enough for casting of wire harnesses, bumpers and model tires.

Gel in seconds and are designed for automated meter/mix dispensing. The Shore D hardness systems include water clear products, high flexural modulus (350,000 psi) materials and polymers with high heat capabilities that can withstand exposure to temperatures up to 284ºF (140ºC) without a post-cure.

Simulate polypropylene, TPO and ABS thermoplastics. The Innovative Polymers materials, based on advanced crosslinked technologies, combine ultra-high impact strength with medium-to-high flexural modulus values and high heat resistance. A flame retardant system that meets UL 94 V-O standards is also available

Continue Reading

Talk to the team

Have questions about a product? Want something custom made just for you?

Get in touch with one of our expert sales-representatives for more information about our products.