When polyurethanes don’t perform as expected, companies typically look for explanations such as technician error, mixing machine issues or supplier/raw materials problems. A common culprit is often overlooked…the weather. Uncontrolled shipping, storing and casting environments can cause polyurethane resins and hardeners to form crystals, altering handling characteristics. Eliminating these issues is frequently as easy as implementing better control over shop temperature and humidity.

Effects on Cure. Shop temperature should be maintained at 70°F to 77°F to ensure polyurethane system stability and consistency. The catalysts and reactive-crosslinkers used to formulate polyurethane materials generate heat when mixed. If the ambient temperature in the shop during mixing and pouring varies greatly from the controlled laboratory temperature of around 72°F, the polyurethane’s gel time will be different than that stated on the technical data sheet. If the temperature is greater than 77°F, the gel time and work life of the mixed system will be reduced and linear shrinkage may increase. Similarly, a lower than “normal” room temperature will increase the gel time and lengthen curing and demolding schedules.

Effects on Shipping. When temperatures hover around 60°F, both resin and hardener system components may begin to freeze. If resin freezes, small white shards or crystals will form or the material will take on a “milky” or cloudy appearance. Hardener subjected to cold temperatures may become more viscous and form “waxy” chunks.

Crystallized resin and hardener usually can be returned to their original, usable state with the application of heat following several easy steps:

NOTE: In rare cases, crystallized or partially solidified materials will have dimerized, or undergone a molecular change, that prevents reclamation.

When polyurethane is exposed to water, the byproduct is CO2. When a polyurethane resin is moisture contaminated or a mixed system is cast in a very humid environment, eradicating the trapped air bubbles is very difficult. In some cases, vacuum and/or pressure can be used to remove air but it’s always easier to prevent the problem in the first place.

Air Conditioner. During summer months, when temperatures and humidity are high, it’s important to use an air conditioner in the areas where polyurethanes will be handled and poured. A relative humidity below 50% is the ideal environment for casting materials. A dehumidifier may also be helpful.

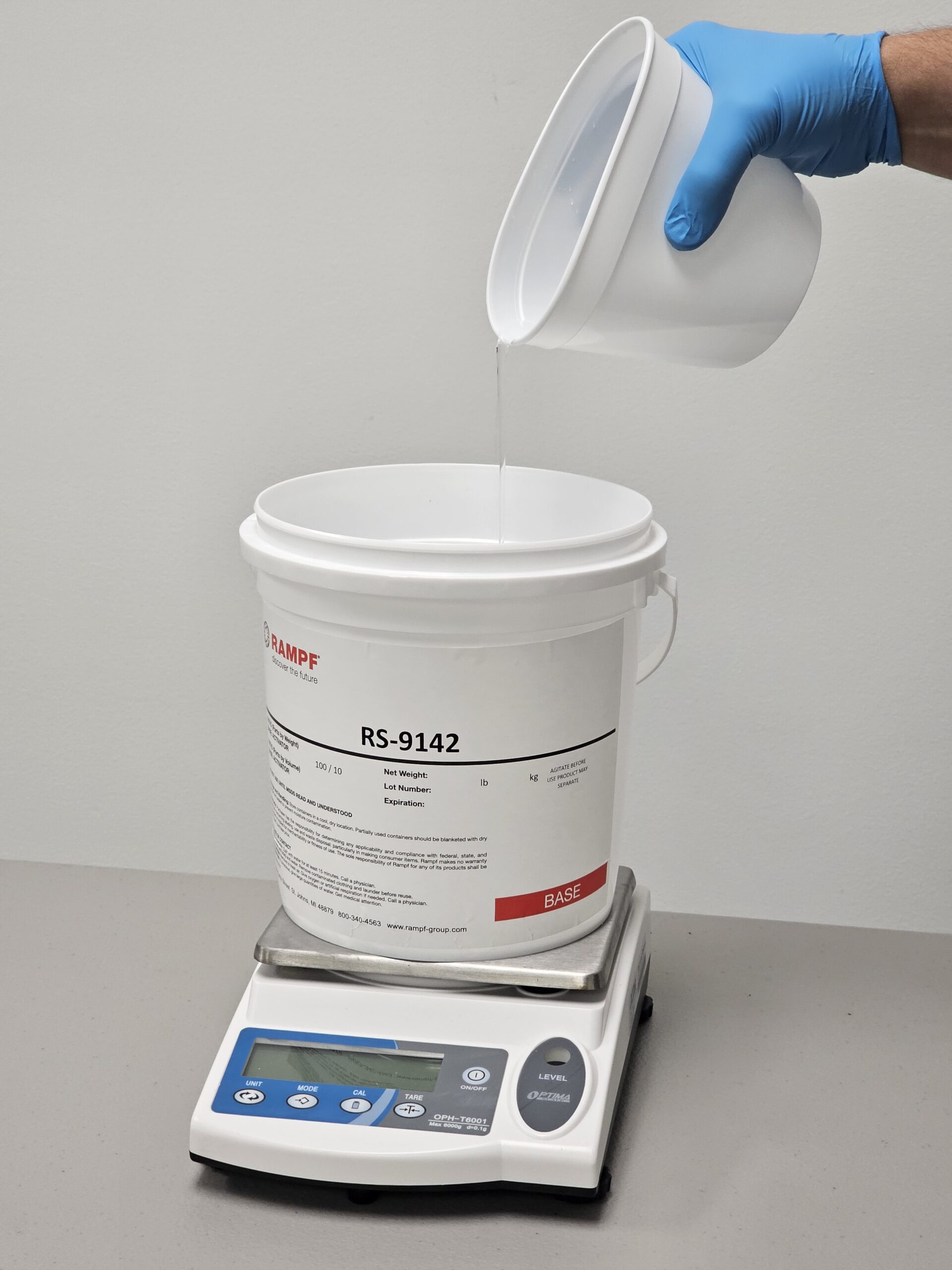

Replace Wood and Paper Products. Exposing polyurethanes to moisture-retaining surfaces can cause bubble formation. For example, paper mixing containers and wooden mixing sticks should be avoided in favor of plastic buckets and paddles. Similarly, silicone, epoxy or aluminum tools are preferable to wood molds.

Dry Nitrogen. When containers are opened to remove resin or hardener, clean the edges with a rag or paper towel to remove residual material. Then, replace the lids and reseal securely. If desired, spray a layer of dry nitrogen into the can before closing. Because the gas is heavier than water vapor, it will settle over the polyurethane surface to prevent contamination. NOTE: RAMPF fluorinates its one-gallon jugs to help protect against moisture migration through the plastic.

Desiccant. When meter/mix equipment is used or material is dispensed from steel drums, a desiccant cartridge should be utilized. The cartridge is designed to dry the air being pulled through it, eliminating the harmful effects of water molecules.

Liquid Protection. Molecular sieves that absorb moisture and block water molecules from reacting are also incorporated in many RAMPF hardener formulations. NOTE: These fillers will settle out of solution, forming a thin white layer at the bottom of the hardener container. Shaking the can will resuspend the sieves.

For more information, contact RAMPF technical service department at 248.295.0223 or e-mail rgi-officestj@rampf-group.com.

Have questions about a product? Want something custom made just for you?

Get in touch with one of our expert sales-representatives for more information about our products.

© 2021 Innovative Polymers - All Rights Reserved

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |