Our polyurethane, epoxy, and silicone-based products – RAKU PUR, RAKU® POX, and RAKU® SIL – offer a wide portfolio of mechanical, thermal, and chemical properties that meet the highest quality requirements. Naturally they are used by leading manufacturers, including the automotive and electronics industries.

Our many years of experience in product development and processing technologies enable us to provide you with comprehensive advice on materials and process engineering.

Our range of competencies includes:

> Production and recycling of materials for modeling, lightweight construction, bonding, and protection

> Technical production systems for precise, dynamic positioning and automation

> A comprehensive range of solutions and services, particularly for innovative and customer-specific requirements

The optimum solutions for your application based on polyurethane, epoxy, and silicone.

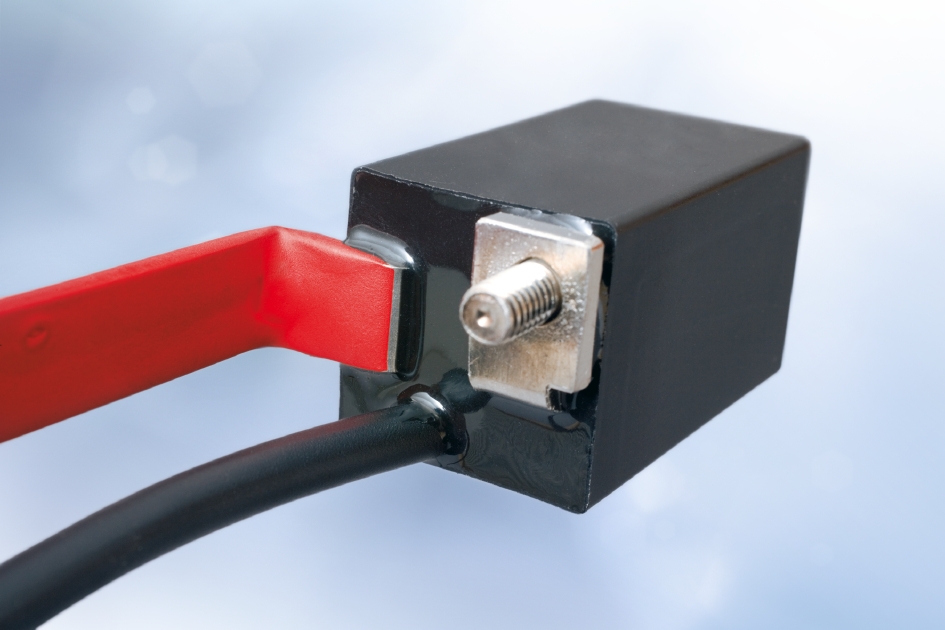

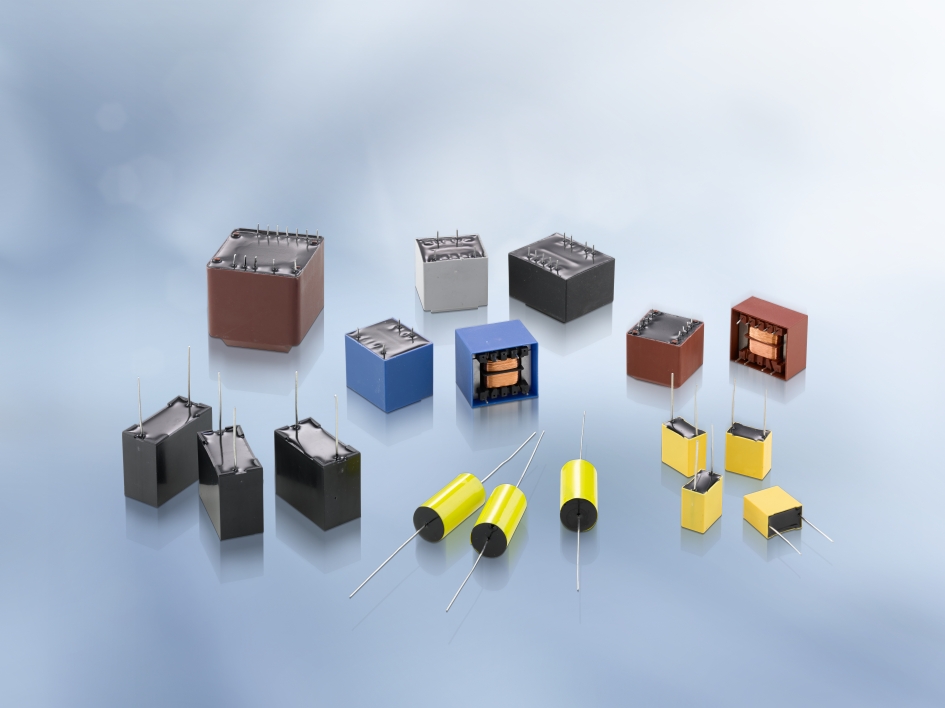

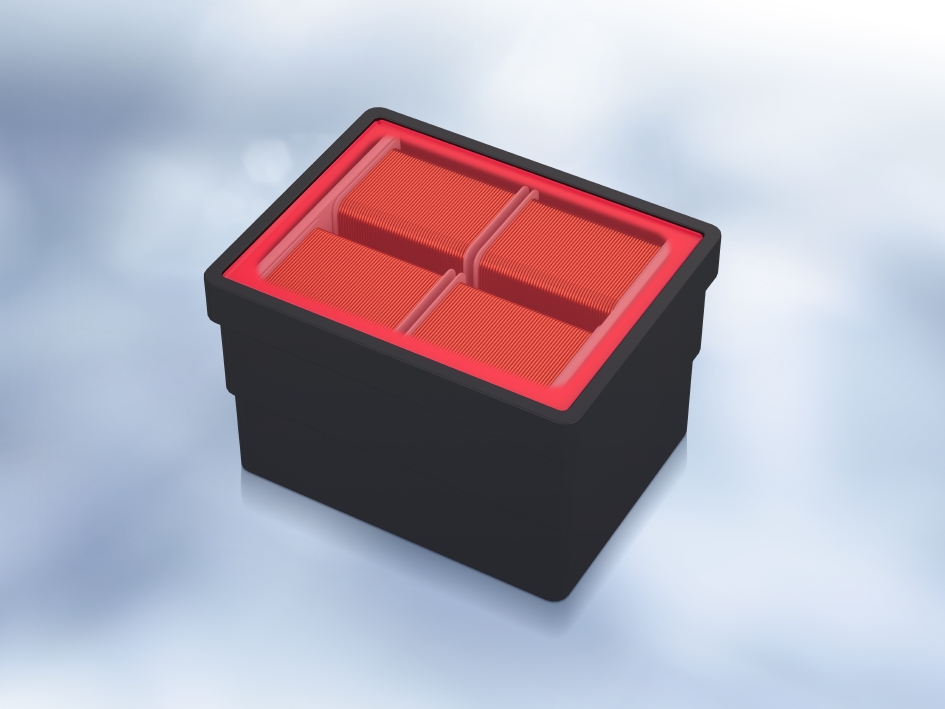

Electro casting resins play a pivotal role in advancing various industries, including automotive, energy, automation, and household goods. The progress in storing and transmitting electricity significantly impacts these sectors.

RAMPF Group, Inc. offers one- and two-component electro casting resins that enhance the reliability and performance of components. Additionally, these resins contribute to cost-efficiency and prolong the service life of components such as transformers, control units, inverters, motors, and more. They provide robust protection against chemical substances and environmental factors like heat, cold, and moisture.

The products, based on polyurethane (RAKU® PUR), epoxy (RAKU® POX), and silicone (RAKU® SIL), are trusted by leading manufacturers in the automotive and electronics industries. These materials exhibit a diverse range of mechanical, thermal, and chemical properties. They effectively conduct heat away from components, ensuring low thermal stresses. Even during extreme temperature fluctuations, the material maintains adequate elasticity to mitigate stresses in the components.

| Polyurethane (RAKU® PUR) | Silicone (RAKU® - SIL) | Epoxy (RAKU® POX) | |

|---|---|---|---|

| Flame retardancy | > UL 94 V0 possible | > UL 94 V0 possible | > UL 94 V0 possible |

| Chemical reaction | > 2-component > Polyaddition reaction > Low exothermic reaction > Curing at room temperature > Curing conditions can be flexibly adjusted by adding a catalyst > Low shrinkage pressure on cast components | > 1- or 2-component > Polyaddition and polycondensation reaction > Low exothermic reaction > Curing at room temperature > Curing can be accelerated using heat > Curing without by-products possible (polyaddition reaction) > Low shrinkage pressure on cast components > Low sensitivity to moisture > Hydrophobic | > 1- or 2-component > Homopolymerization (1-component) and polyaddition reaction (2-component) > Curing at room temperature > Curing can be accelerated using heat > Heat curing required for 1-component and hot-curing epoxy > Good impregnation properties > Low sensitivity to moisture |

| Application range | > Application temperature range: -60 to +155°C Short-term: +160°C > Wide range of mechanical properties, from tough to highly elastic | > Wide application temperature range: -60 to +200°C Short-term: +250°C > Best physical properties almost constant across the entire temperature range of the application | > Application temperature range: -40 to +180°C Short-term: +200°C |

| Properties | > Excellent resistance to fluctuations in temperature for sensitive components > High crack resistance of flexible products > Good chemical resistance > Low water absorption > Good electrical properties > Tg: From -75 to +120°C > RTI: To +155°C > OBJS2-listed | > Excellent resistance to fluctuations in temperature > High crack resistance > Excellent chemical resistance for extreme environments > Low water absorption > High water vapor permeability > High UV and weather resistance > Tg: always < 0°C | > High heat distorsion temperature > Low coefficient of thermal expansion > High dielectric strength > High media resistance to fuels > Low water absorption and water vapor permeability > Tg: -20 to +180°C > OBJS2-listed |

| Bonding | > Good adhesion to housings and components > Good adhesion to plastic: PA, PBT, ABS | > Good adhesion to mineral substrates > Adhesion to other substrates often only with pretreatment | > Good adhesion to metals |

| Product | Mixing Ratio | Viscosity [mPa*s] | Pot life [min] | Hardness [Shore D] | Thermal Conductivity [W/(m*k)] | Operating temperature [°C] | Characteristics | Approvals |

|---|---|---|---|---|---|---|---|---|

| 21-2350 | 100:16 | 4,000 | 45 | 48 | 0.84 | -40 - + 130 | UL 94 V0 3 mm | RTI listed at 130°C (File E111148) |

| 21-2360-1 | 100:15 | 9,000 | 38 | 71 | 1.09 | -40 - + 130 | UL 94 V0 1.5mm | --- |

| 21-2560-7 | 100:20 | 7,000 | 50 | 83 | 0.75 | -40 - + 130 | UL 94 V0 6mm | OBJ System Components, Electrical Insulation, (File OBJS2.E365009 130°C Class B |

COMING SOON

| Product | Mixing Ratio | Viscosity | Pot Life 20°C [min] | Hardness [Shore] | Thermal Conductivity [W/m*K)] | Operating Temperature [°C] |

|---|---|---|---|---|---|---|

| 27-1018 | 100:100 | 215,000 | 120 | 55 [00] | 2.6 | -40 to +150 |

| 27-1019 | 100:100 | 115,000 | 210 | 45 [00] | 1.7 | -45 to +200 |

| 27-1004 | 100:100 | 100,000 | 35 | 20 [A] | 1.7 | -60 to +200 |

Have questions about a product? Want something custom made just for you?

Get in touch with one of our expert sales-representatives for more information about our products.

© 2021 Innovative Polymers - All Rights Reserved

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |