How to Mold and Cast Climbing Holds

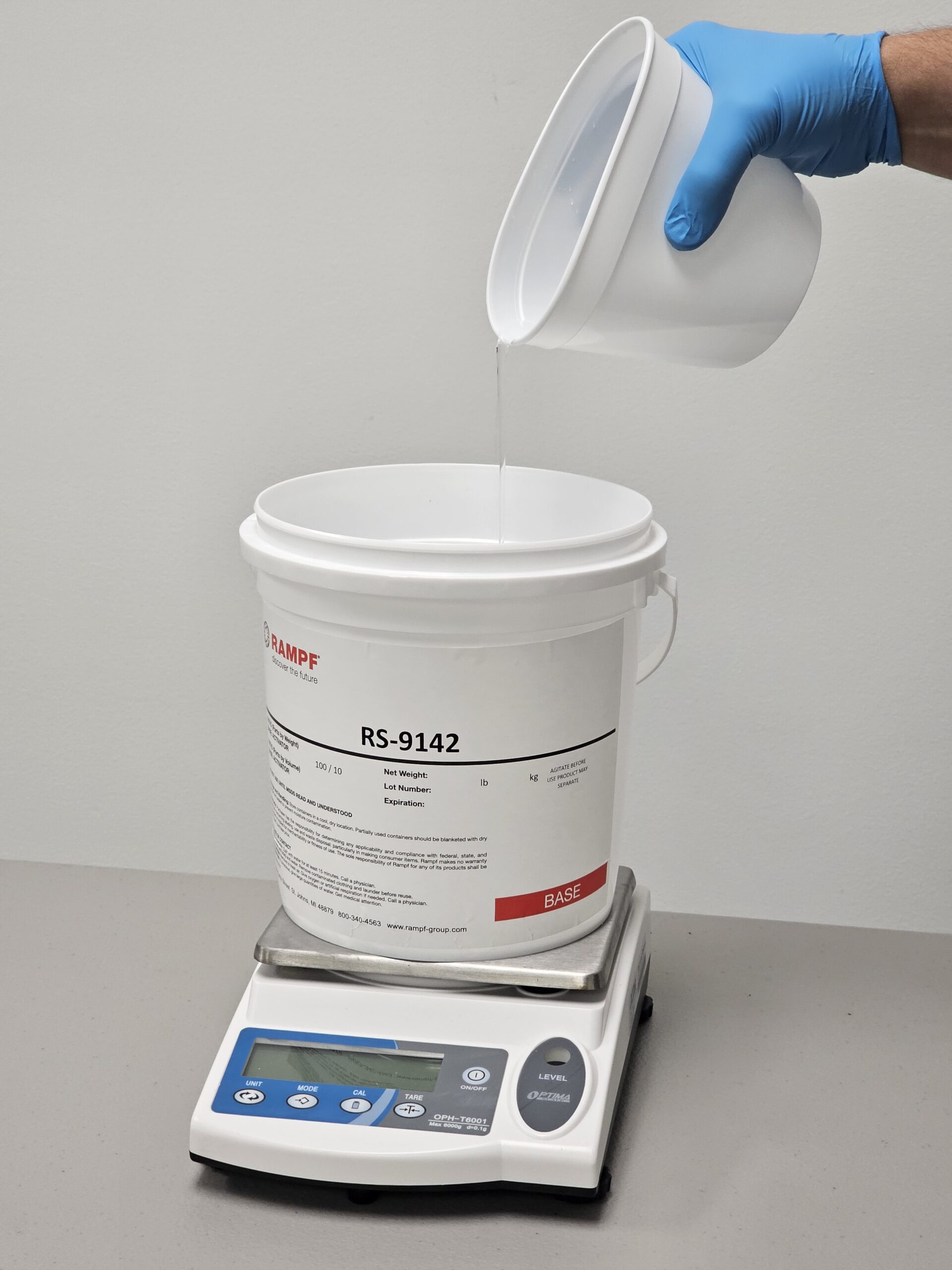

Making a Silicone Mold: Materials needed to make a mold: (Silicone and Polyurethane available here!) RS-9225 is a 25 Shore A Tin Silicone with a mix ratio by weight of 10 parts White Base material to 1 part Blue Activator.