Castable Urethanes

RAMPF specializes in providing technologically advanced polyurethanes for the toughest applications. Our technical support team welcomes the opportunity to collaborate with our customers in solving processing and performance challenges. If an existing product does not meet project requirements, our experienced chemists are well equipped to formulate new materials to satisfy the most exacting specifications.

RAMPF manufactures our versatile range of polyurethane products using state-of-the-art processing to ensure that materials conform to established performance criteria with excellent uniformity and consistency. Rigorous quality control testing is conducted on each batch of materials to verify and record properties before shipment to customers.

RAMPF emphasizes fast response to customer needs. We maintain a flexible production schedule that accommodates shipping of most orders on a same-day or next-day basis. RAMPF also offer our customers a color-match service that is second-to-none in speed and cost with a typical 48-hour turn-around time for color proofs.

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time min | Viscosity cP | Flex Mod psi | Notched Izod ft-lb/in | Add to Cart |

|---|---|---|---|---|---|---|---|---|---|

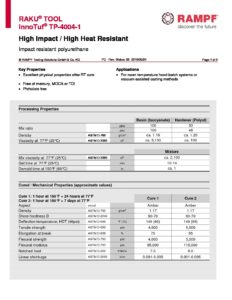

| TP-4004-1 |  |

60-70D | Amber | 100:50 | 10-14 | 2,100 | 115,000 | 6.0 | Add to Cart |

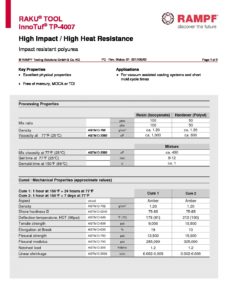

| TP-4007 |  |

75-85D | Amber | 100:50 | 8-12 | 400 | 325,000 | 1.2 | Add to Cart |

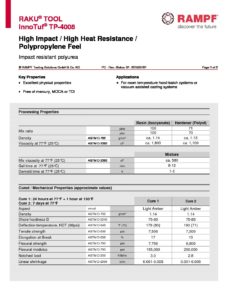

| TP-4008 |  |

75-85D | Light Amber | 100:71 | 8-12 | 580 | 200,000 | 2.8 | Add to Cart |

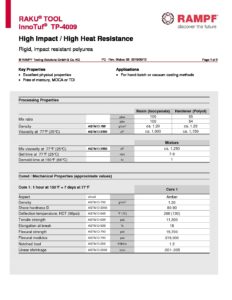

| TP-4009 |  |

80-90D | Amber | 100:55 | 7-9 | 1,275 | 316,000 | 1.2 | Add to Cart |

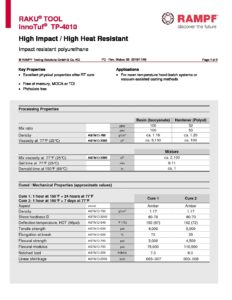

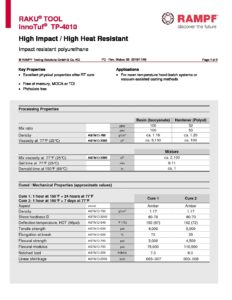

| TP-4010 |  |

60-70D | Amber | 100:52 | 8-11 | 2,100 | 110,500 | 6.0 | Add to Cart |

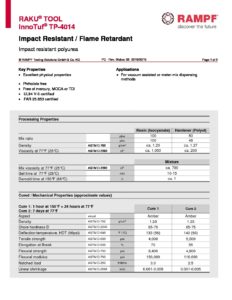

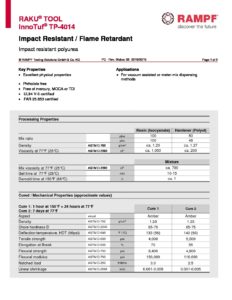

| TP-4014 |  |

65-75D | Amber | 100:48 | 10-15 | 1,050 | 150,000 | 3.0 | Add to Cart |

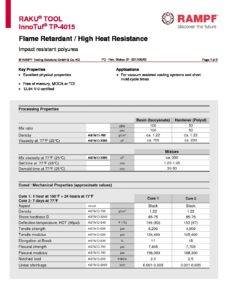

| TP-4015 |  |

65-75D | Black | 100:50 | 1:25 - 1:35 | 350 | 168,300 | 2.5 | Add to Cart |

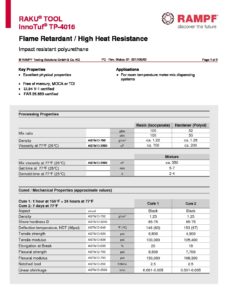

| TP-4016 |  |

65-75D | Black | 100:52 | 5-7 | 350 | 168,300 | 2.5 | Add to Cart |

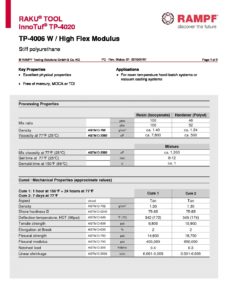

| TP-4020 |  |

75-85D | Tan | 100:46 | 8-12 | 1,300 | 650,000 | 0.3 | Add to Cart |

| TP-4040 |  |

65-75D | Black | 100:53 | 1:30 - 2:30 | 2,100 | 110,000 | 6.5 | |

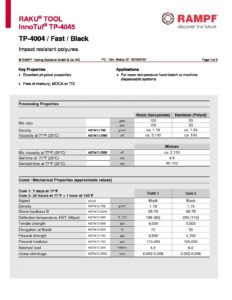

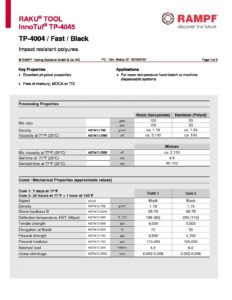

| TP-4045 |  |

65-75D | Black | 100:53 | 4-6 | 2,100 | 110,000 | 6.5 | Add to Cart |

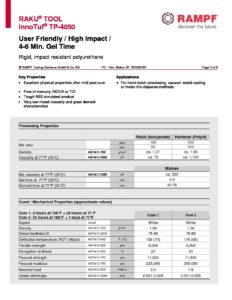

| TP-4050 |  |

75-85D | White | 100:100 | 4-6 | 325 | 250,000 | 1.8 | Add to Cart |

| TP-4052 |  |

75-85D | White | 100:50 | 5-9 | 600 | 250,000 | 1.7 | Add to Cart |

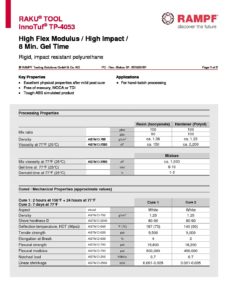

| TP-4053 |  |

80-90D | White | 100:100 | 6-10 | 1,000 | 450,000 | 0.7 | Add to Cart |

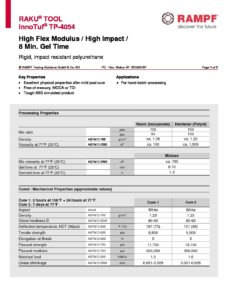

| TP-4054 |  |

80-90D | White | 100:100 | 6-10 | 700 | 350,000 | 1.0 | Add to Cart |

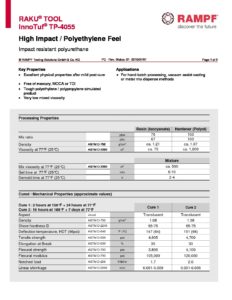

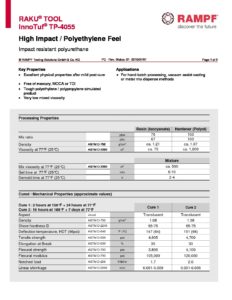

| TP-4055 |  |

65-75D | Translucent | 76:100 | 6-10 | 500 | 120,000 | 2.0 | Add to Cart |

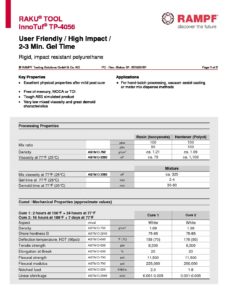

| TP-4056 |  |

75-85D | White | 100:100 | 2-4 | 325 | 250,000 | 1.8 | Add to Cart |

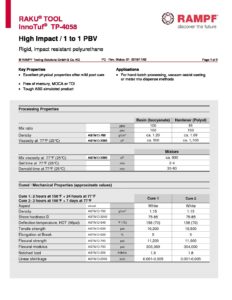

| TP-4058 |  |

75-85D | White | 100:91 | 2-4 | 900 | 304,000 | 1.8 | Add to Cart |

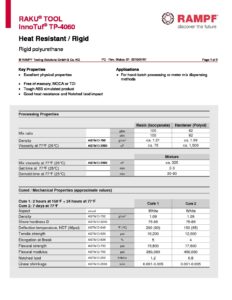

| TP-4060 |  |

75-85D | White | 100:82 | 2-3 | 325 | 450,000 | 0.8 | |

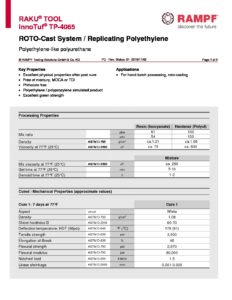

| TP-4065 |  |

60-70D | White | 61:100 | 7-10 | 250 | 80,000 | 1.5 | |

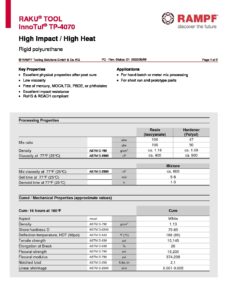

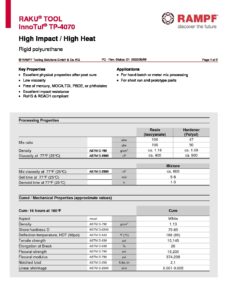

| TP-4070 |  |

75-85D | White | 100:47 | 5-8 | 600 | 374,238 | 2.1 | |

| TP-4071 |  |

75-85D | White | 100:47 | 10-14 | 600 | 374,238 | 2.1 | |

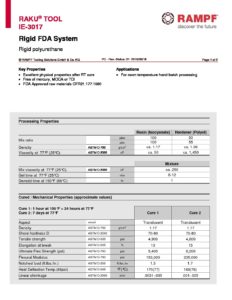

| IE-3017 FDA |  |

70-80D | White | 100:55 | 8-12 | 250 | 235,000 | 1.7 | Add to Cart |

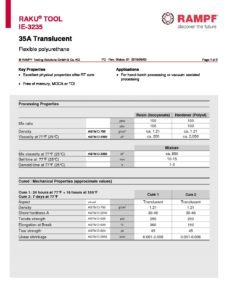

| IE-3025 |  |

65-75D | Translucent | 100:94 | 2:30-3:30 | 100 | 200,000 | 0.6 | Add to Cart |

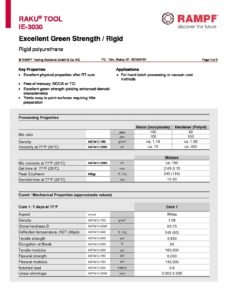

| IE-3030 |  |

65-75D | White | 100:92 | 2:45-3:15 | 150 | 145,000 | 0.6 | Add to Cart |

| IE-3065 |  |

65-75D | Light Gray | 100:97 | 4-8 | thixotropic | 635,000 | 0.6 | Add to Cart |

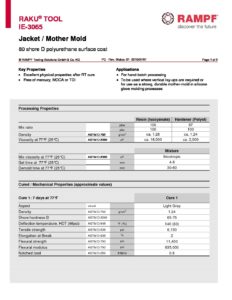

| IE-3067 |  |

65-75D | White | 100:91 | 2-4 | thixotropic | 635,000 | 0.6 | |

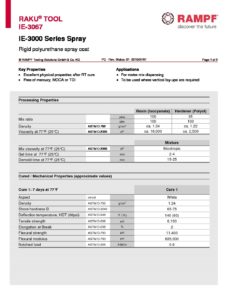

| IE-3070 |  |

65-75D | White | 100:92 | 6-10 | 150 | 145,000 | 0.6 | Add to Cart |

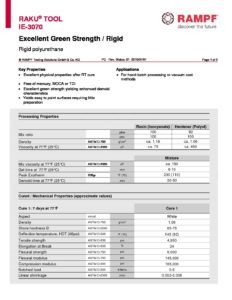

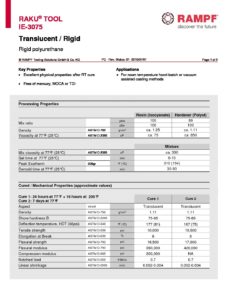

| IE-3075 |  |

75-85D | Translucent | 100:89 | 6-10 | 300 | 420,000 | 0.7 | Add to Cart |

| IE-3077 |  |

70-80D | Translucent | 100:94 | 4-6 | 100 | 267,000 | 0.6 | Add to Cart |

| IE-3080 |  |

65-75D | Translucent | 100:94 | 7-9 | 100 | 200,000 | 0.6 | Add to Cart |

| IE-3092 |  |

70-80D | Translucent | 100:100 | 8-12 | 250 | 250,000 | 0.8 | Add to Cart |

| IE-3092-1 |  |

70-80D | Translucent | 100:90 | 6-8 | 150 | 250.000 | 0.80 | Add to Cart |

| IE-3461 |  |

55-65D | Beige | 100:98 | 4-6 | 2,500 | 175,000 | 0.80 | |

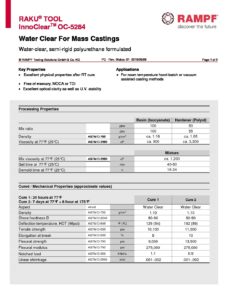

| OC-5085 |  |

75-85D | Water Clear | 100:57 | 80-120 | 650 | 350,000 | 0.3 | Add to Cart |

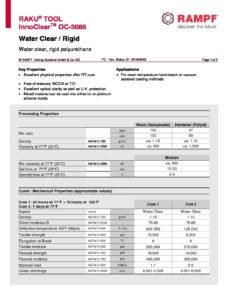

| OC-5086 |  |

75-85D | Clear | 100:57 | 15-20 | 450 | 345,000 | 1.1 | Add to Cart |

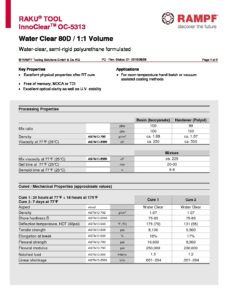

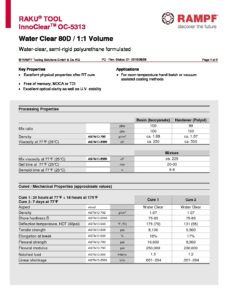

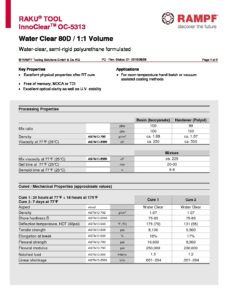

| OC-5313 |  |

75-85D | Water Clear | 100:100 | 20-30 | 225 | 250,000 | 1.5 | |

| FX-8113 |  |

75-85D | Amber | 100:100 | 8-12 | 550 | 270,000 | 1.1 | Add to Cart |

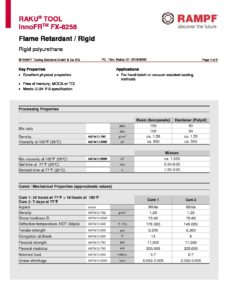

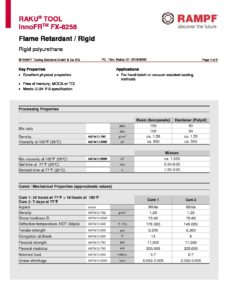

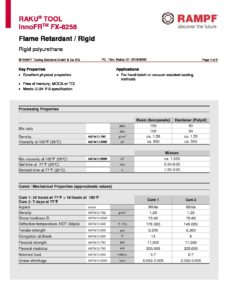

| FX-8258 |  |

75-85D | White | 100:50 | 5:30-8:30 | 1,000 | 300,000 | 0.7 | |

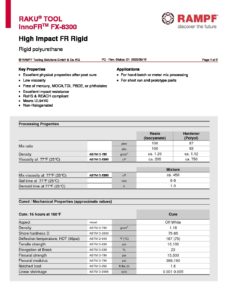

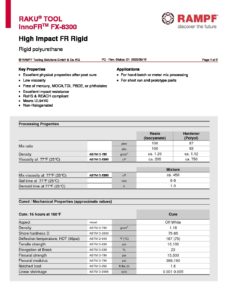

| FX-8300 |  |

75-85D | Off White | 100:87 | 6-8 | 450 | 386,190 | 1.6 | |

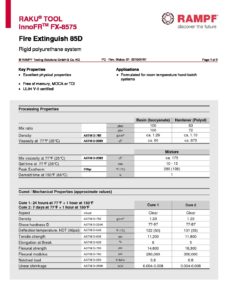

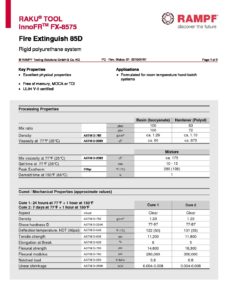

| FX-8575 |  |

77-87D | Clear | 100:63 | 10-15 | 175 | 350,000 | 0.8 | Add to Cart |

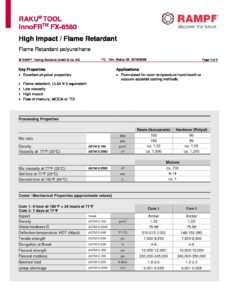

| FX-8580 |  |

75-85D | Amber | 100:60 | 8-14 | 700 | 250,000 | 1.8 | Add to Cart |

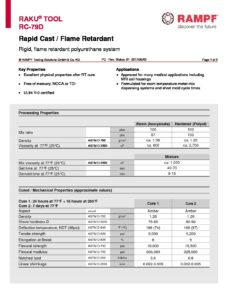

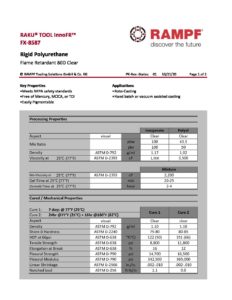

| RC-79D |  |

80-90D | Amber | 100:100 | 40-70 sec | 1,000 | 325,000 | 0.6 | |

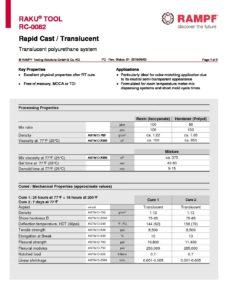

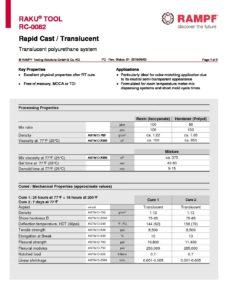

| RC-0082 |  |

75-85D | Translucent | 100:86 | 40-60 sec | 375 | 285,000 | 0.7 | Add to Cart |

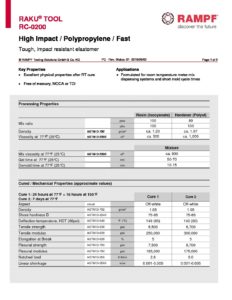

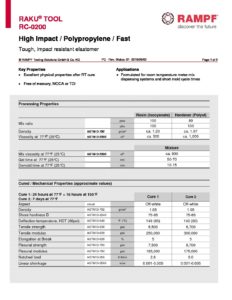

| RC-0200 |  |

75-85D | Off-White | 100:89 | 50-70 sec | 900 | 175,000 | 3.0 | |

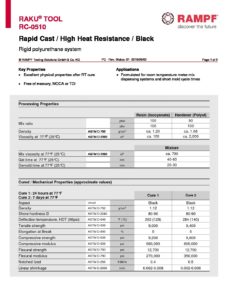

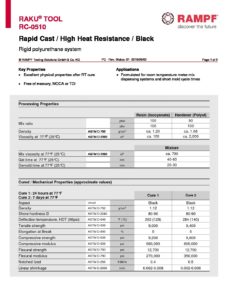

| RC-0510 |  |

80-90D | Black | 100:90 | 40-60 sec | 700 | 350,000 | 0.5 | Add to Cart |

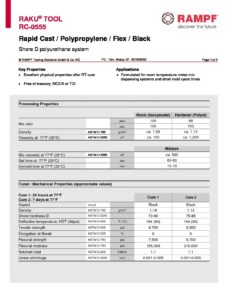

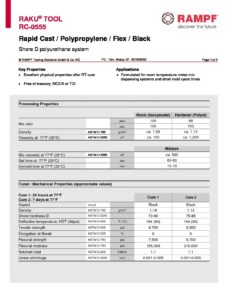

| RC-0555 |  |

75-85D | Black | 100:88 | 60-80 sec | 500 | 210,000 | 1.1 | Add to Cart |

| RC-0900 |  |

80-90D | Amber | 100:90 | 70-90 sec | 425 | 350,000 | 0.8 | Add to Cart |

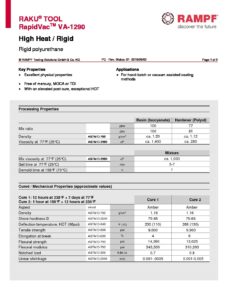

| VA-1290 |  |

75-85D | Amber | 100:77 | 5-7 | 1,000 | 343,500 | 0.7 |

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time min | Viscosity cps | Tear Strength pli | Notched Izod ft-lb/in | Add to Cart |

|---|---|---|---|---|---|---|---|---|---|

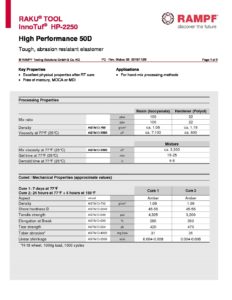

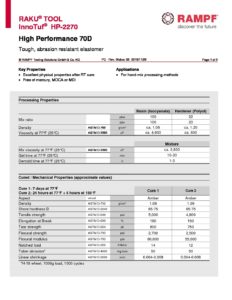

| HP-2250 |  |

45-55D | Amber | 100:22 | 15-25 | 3,300 | 420 | --- | Add to Cart |

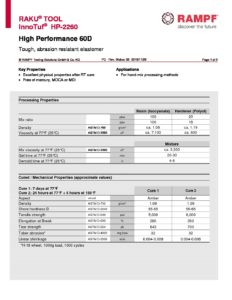

| HP-2260 |  |

55-65D | Amber | 100:20 | 20-30 | 3,300 | 643 | --- | Add to Cart |

| HP-2270 |  |

65-75D | Amber | 100:22 | 10-20 | 3,800 | 800 | 14.0 | Add to Cart |

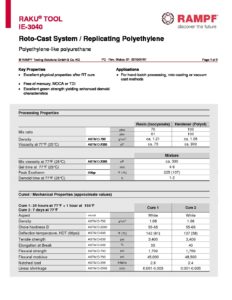

| IE-3040 |  |

55-65D | White | 70:100 | 4-6 | 300 | --- | 2.4 | Add to Cart |

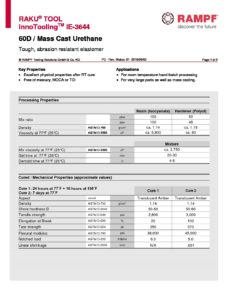

| IE-3644-1 |  |

50-60D | Translucent Amber | 100:50 | 20-30 | 2,750 | 350 | --- | Add to Cart |

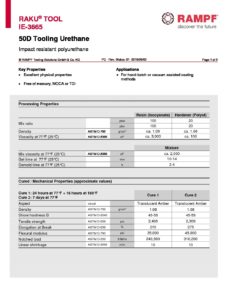

| IE-3665 |  |

45-55D | Translucent Amber | 100:20 | 10-14 | 2,200 | --- | 10 | |

| TP-4004-1 |  |

60-70D | Amber | 100:50 | 10-14 | 2,100 | --- | 7.0 | Add to Cart |

| TP-4010 |  |

60-70D | Amber | 100:52 | 8-11 | 2,100 | --- | 7.0 | Add to Cart |

| TP-4014 |  |

65-75D | Amber | 100:50 | 10-15 | 700 | --- | 3.0 | Add to Cart |

| TP-4045 |  |

65-75D | Black | 100:53 | 4-6 | 2,100 | --- | 6.5 | Add to Cart |

| TP-4055 |  |

65-75D | Translucent | 76:100 | 6-10 | 500 | --- | 1.7 | Add to Cart |

RAMPF flexible urethane can be used to create versatile parts with excellent tear strength and elongation. Used in a wide variety of applications, RAMPF urethane elastomers is an industry favorite for producing high quality, long-lasting products including: military training aids, material handling nests, automotive components, industrial matting, medical education models, and more.

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time min | Viscosity cps | Tear Strength pli | Tensile Strength psi | Add to Cart |

|---|---|---|---|---|---|---|---|---|---|

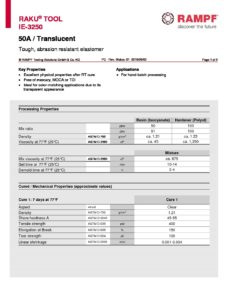

| IE-3235 |  |

30-40A | Translucent | 100:100 | 10-15 | 850 | 45 | 200 | Add to Cart |

| IE-3240 |  |

32-42A | Off-White | 100:95 | 20-30 | 950 | 75 | 900 | Add to Cart |

| IE-3250 |  |

45-55A | Clear | 50:100 | 10-14 | 875 | 100 | 400 | Add to Cart |

| IE-3251 |  |

60-70A | Gray | 56:100 | 22-32 | 1,950 | 105 | 700 | Add to Cart |

| IE-3252 |  |

45-55A | Off-White | 40:100 | 20-30 | 800 | 120 | 900 | Add to Cart |

| IE-3253 |  |

60-70A | Translucent | 100:92 | 7-10 | 1,300 | 150 | 1100 | Add to Cart |

| IE-3254 |  |

45-55A | Bronze | 61:100 | 10-15 | 875 | 100 | 400 | Add to Cart |

| IE-3257 |  |

45-55A | White | 16:100 | 9-15 | 775 | 25 | 200 | Add to Cart |

| IE-3260 |  |

50-60A | Cream | 25:100 | 7-13 | 975 | 100 | 800 | Add to Cart |

| IE-3261 |  |

55-65A | Clear | 50:100 | 9-15 | 575 | 75 | 500 | Add to Cart |

| IE-3262 |  |

55-65A | Tan | 50:100 | 9-15 | 575 | 110 | 550 | Add to Cart |

| IE-3270 |  |

65-75A | Cream | 34:100 | 7-13 | 975 | 180 | 1,700 | Add to Cart |

| IE-3273 |  |

65-75A | White | 30:100 | 7-13 | 775 | 45 | 500 | Add to Cart |

| IE-3275 |  |

70-80A | White | 95:100 | 30-60 | 675 | 80 | 800 | Add to Cart |

| IE-3280 |  |

75-85A | Cream | 35:100 | 7-13 | 975 | 180 | 1,700 | Add to Cart |

| IE-3285 |  |

75-85A | Black | 100:13 | 20-30 | 3,100 | 200 | 1,300 | Add to Cart |

| IE-3288 |  |

75-85A | White | 37:100 | 7-13 | 775 | 110 | 1,000 | Add to Cart |

| IE-3290 |  |

80-90A | Cream | 38:100 | 7-13 | 975 | 215 | 1,750 | Add to Cart |

| IE-3500 |  |

35-45A | Light Amber | 60:100 | 16-20 | 2,000 | 75 | 450 | Add to Cart |

| IE-3600 |  |

55-65A | Light Amber | 60:100 | 16-20 | 2,000 | 65 | 450 | Add to Cart |

| IE-3700 |  |

65-75A | Cream | 59:100 | 16-20 | 2,000 | 125 | 800 | |

| IE-3800 |  |

75-85A | Cream | 35:100 | 16-20 | 2,000 | 230 | 1,170 | |

| HP-2130 |  |

25-35A | Light Amber | 100:45 | 20-30 | 475 | --- | 350 | |

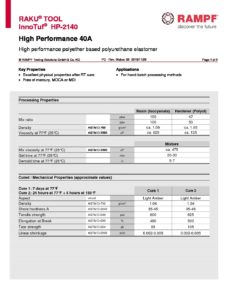

| HP-2140 |  |

35-45A | Light Amber | 100:47 | 30-30 | 475 | --- | 600 | |

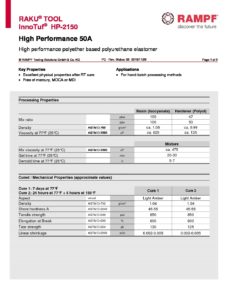

| HP-2150 |  |

45-55A | Light Amber | 100:47 | 20-3 | 475 | --- | 850 | Add to Cart |

| HP-2160 |  |

55-65A | Light Amber | 100:43 | 10-20 | 1,660 | --- | 900 | Add to Cart |

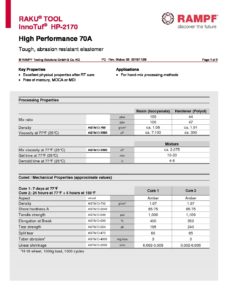

| HP-2170 |  |

65-75A | Amber | 100:44 | 10-20 | 2,075 | --- | 1,000 | Add to Cart |

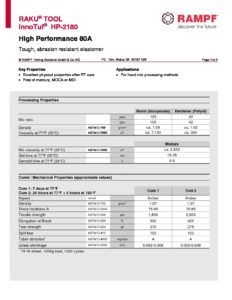

| HP-2180 |  |

75-85A | Amber | 100:40 | 15-25 | 2,800 | --- | 1,800 | Add to Cart |

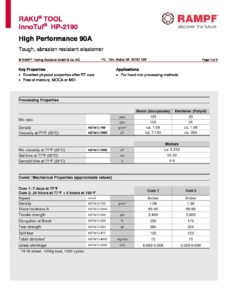

| HP-2190 |  |

85-95A | Amber | 100:30 | 20-30 | 3,300 | --- | 3,400 | Add to Cart |

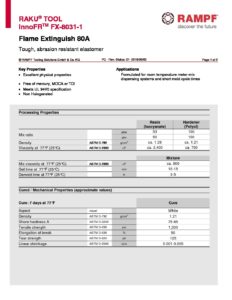

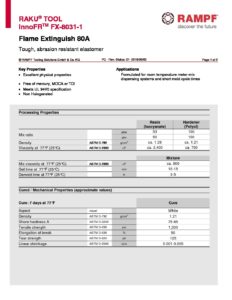

| FX-8031-1 |  |

75-85A | White | 53:100 | 25-35 | 800 | 125 | 1,200 | Add to Cart |

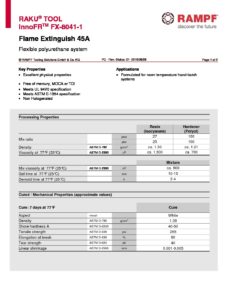

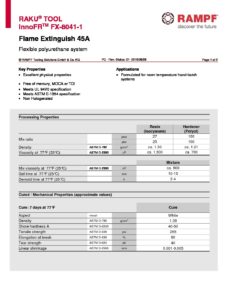

| FX-8041-1 |  |

40-50A | White | 27:100 | 10-15 | 800 | 40 | 255 | Add to Cart |

| FX-8061-1 |  |

55-65A | White | 36:100 | 10-15 | 800 | 75 | 525 | Add to Cart |

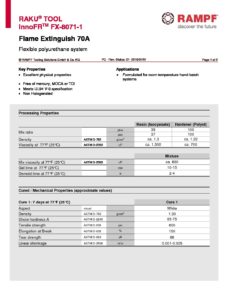

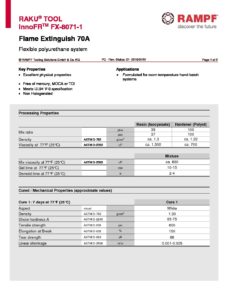

| FX-8071-1 |  |

65-75A | White | 39:100 | 10-15 | 1,850 | 86 | 600 | Add to Cart |

| FX-8081-1 |  |

75-85A | White | 44:100 | 10-15 | 800 | 135 | 1,050 | Add to Cart |

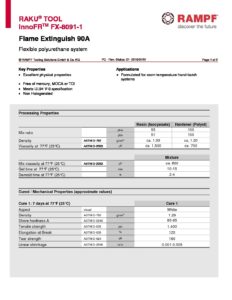

| FX-8091-1 |  |

85-95A | White | 55:100 | 10-15 | 800 | 160 | 1,400 | Add to Cart |

| FX-8258 |  |

75-85D | White | 100:50 | 5:30 - 8:30 | 1,000 | ___ | 6,200 | Add to Cart |

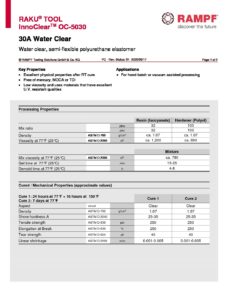

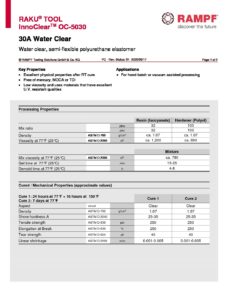

| OC-5030 |  |

25-35A | Clear | 32:100 | 15-25 | 1,200 | --- | 250 | |

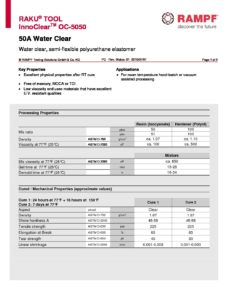

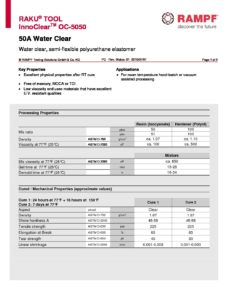

| OC-5050 |  |

45-55A | Clear | 50:100 | 15-25 | 650 | --- | 225 | Add to Cart |

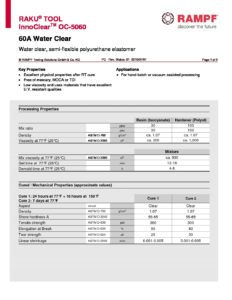

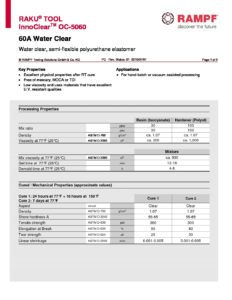

| OC-5060 |  |

55-65A | Clear | 30:100 | 12-18 | 900 | --- | 300 | Add to Cart |

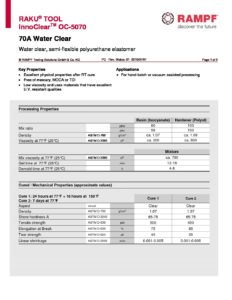

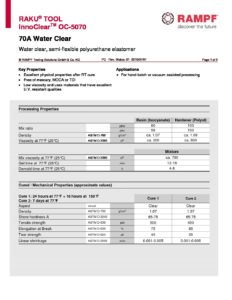

| OC-5070 |  |

65-75A | Clear | 60:100 | 12-18 | 700 | --- | 450 | Add to Cart |

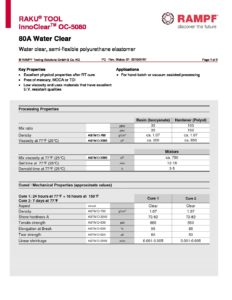

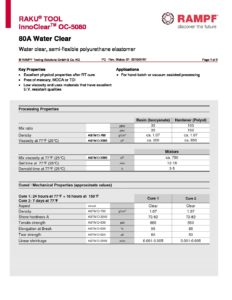

| OC-5080 |  |

72-82A | Clear | 35:100 | 12-18 | 750 | --- | 550 | Add to Cart |

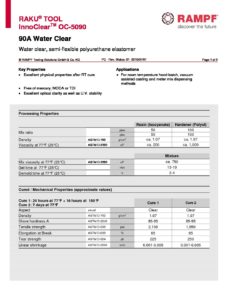

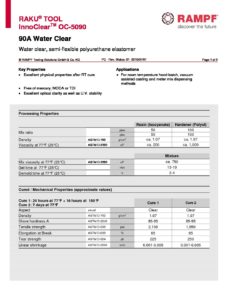

| OC-5090 |  |

85-95A | Clear | 50:100 | 13-19 | 750 | 250 | 1,950 | Add to Cart |

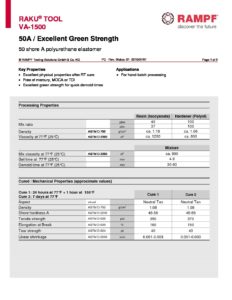

| VA-1500 |  |

45-55A | Neutral Tan | 40:100 | 4-6 | 900 | 40 | 370 | |

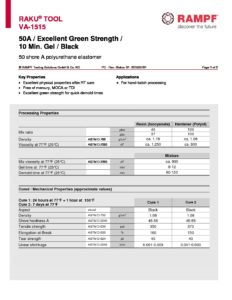

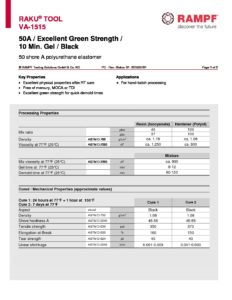

| VA-1515 |  |

45-55A | Black | 40:100 | 8-12 | 900 | 40 | 350 | Add to Cart |

| VA-1600 |  |

55-65A | Neutral Tan | 52:100 | 3-5 | 850 | 40 | 325 | |

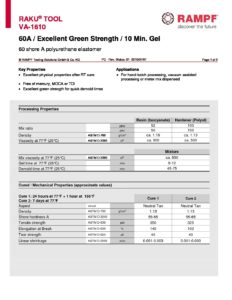

| VA-1610 |  |

55-65A | Neutral Tan | 52:100 | 8-12 | 850 | 40 | 350 | Add to Cart |

| VA-1615 |  |

55-65A | Black | 52:100 | 8-12 | 850 | 40 | 350 | Add to Cart |

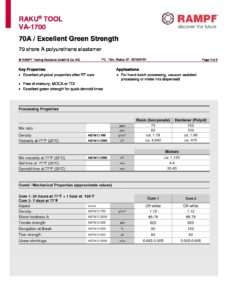

| VA-1700 |  |

65-75A | Off-White | 70:100 | 4-6 | 1,110 | 60 | 635 | Add to Cart |

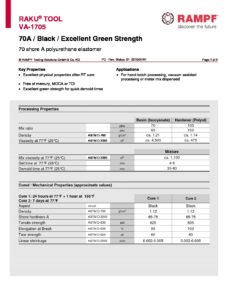

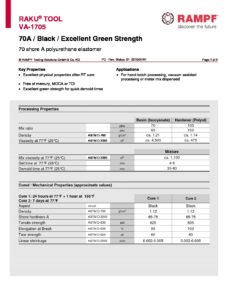

| VA-1705 |  |

65-75A | Black | 70:100 | 4-6 | 1,110 | 60 | 620 | Add to Cart |

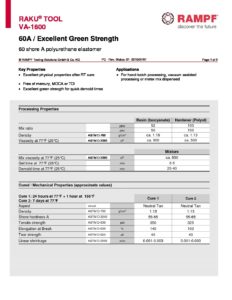

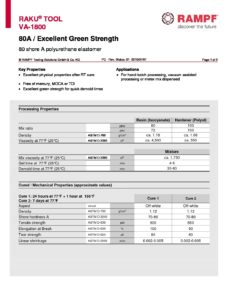

| VA-1800 |  |

70-80A | Off-White | 80:100 | 4-6 | 1,750 | 60 | 650 | Add to Cart |

| VA-1805 |  |

70-80A | Black | 80:100 | 4-6 | 1,750 | 80 | 900 | Add to Cart |

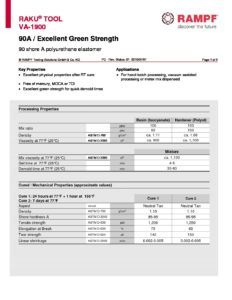

| VA-1900 |  |

85-95A | Neutral Tan | 100:100 | 4-6 | 1,100 | 130 | 1,250 | Add to Cart |

| VA-1915 |  |

85-95A | Black | 100:100 | 8-12 | 1,100 | 140 | 1,200 | Add to Cart |

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time min | Viscosity cps | Flex Mod. psi | Notched Izod ft-lb/in | Add to Cart |

|---|---|---|---|---|---|---|---|---|---|

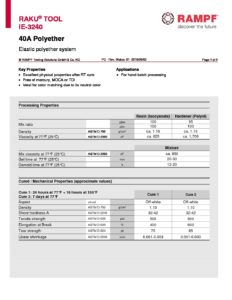

| OC-5030 |  |

25-35A | Clear | 32:100 | 15-25 | 790 | --- | --- | |

| OC-5050 |  |

45-55A | Clear | 50:100 | 15-25 | 650 | --- | --- | Add to Cart |

| OC-5060 |  |

55-65A | Clear | 30:100 | 12-18 | 900 | --- | --- | Add to Cart |

| OC-5070 |  |

65-75A | Clear | 600:100 | 12-18 | 700 | --- | --- | Add to Cart |

| OC-5080 |  |

72-82A | Clear | 35:100 | 12-18 | 750 | --- | --- | Add to Cart |

| OC-5085 |  |

75-85D | Water Clear | 100:57 | 80-100 | 650 | 350,000 | 0.3 | Add to Cart |

| OC-5086 |  |

75-85D | Water Clear | 100:57 | 15-20 | 650 | 350,000 | 0.5 | Add to Cart |

| OC-5090 |  |

85-95A | Clear | 50:100 | 13-19 | 750 | --- | --- | Add to Cart |

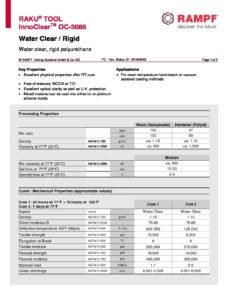

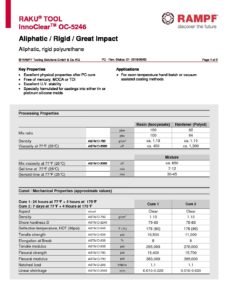

| OC-5246 |  |

75-85D | Clear | 100:62 | 7-12 | 650 | 383,000 | 1.1 | |

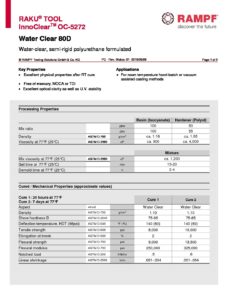

| OC-5272 |  |

75-85D | Water Clear | 100:50 | 15-20 | 1,200 | 325,000 | 0.6 | Add to Cart |

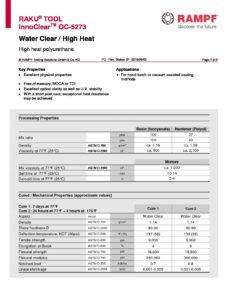

| OC-5273 |  |

80-90D | Water Clear | 100:37 | 10-14 | 1,000 | 350,000 | 0.7 | Add to Cart |

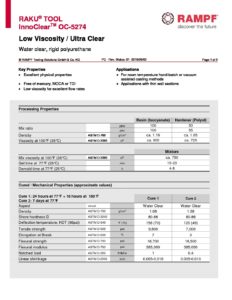

| OC-5274 |  |

80-86D | Water Clear | 100:50 | 15-23 | 750 | 385,000 | 0.4 | Add to Cart |

| OC-5284 |  |

80-90D | Water Clear | 100:50 | 40-60 | 1,200 | 275,000 | 1.1 | Add to Cart |

| OC-5313 |  |

75-85D | Water Clear | 100:92 | 20-30 | 225 | 250,000 | 1.5 | Add to Cart |

| OC-5320 |  |

75-85D | Water Clear | 100:62 | 30-40 | 650 | 345,000 | 1.0 | Add to Cart |

| OC-5436 |  |

80-85D | Transparent | 100:56 | 18-22 | 730 | 390,000 | 1.0 | Add to Cart |

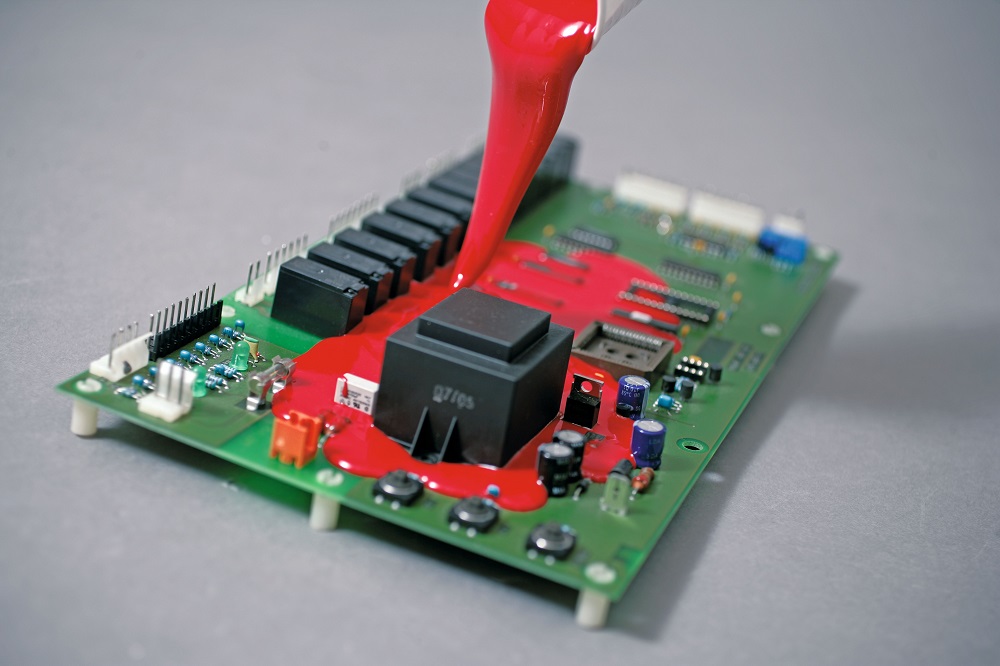

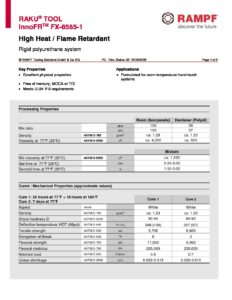

Materials to create long-lasting, flame retardant products ranging from electronic parts to medical devices, gaming machine components and automotive parts. Inno-FR™ liquid plastic casting resins meet UL 94 V-O requirements. Several of the polyurethanes are Yellow Card certified at Underwriters Laboratories (UL). Polymers in the Inno-FR™ Series include:

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time min | Viscosity cps | Flex Mod. psi | Notched Izod ft-lb/in | Add to Cart |

|---|---|---|---|---|---|---|---|---|---|

| FX-8031-1 |  |

75-85A | White | 53:100 | 10-15 | 800 | - | - | Add to Cart |

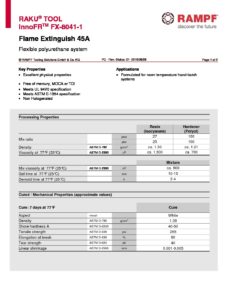

| FX-8041-1 |  |

40-50A | White | 27:100 | 10-15 | 800 | --- | --- | Add to Cart |

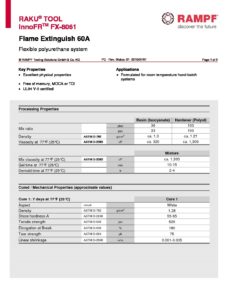

| FX-8061-1 |  |

55-65A | White | 36:100 | 10-15 | 800 | --- | --- | Add to Cart |

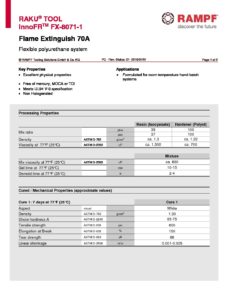

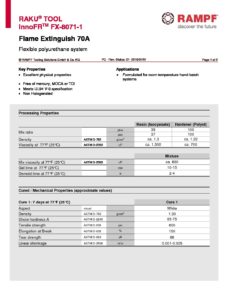

| FX-8071-1 |  |

65-75A | White | 39:100 | 10-15 | 1,850 | --- | --- | Add to Cart |

| FX-8081-1 |  |

75-85A | White | 44:100 | 10-15 | 1,850 | --- | --- | Add to Cart |

| FX-8085 |  |

80-90A | White | 100:100 | 8-12 | 4,400 | --- | --- | |

| FX-8091-1 |  |

85-95A | White | 55:100 | 8-12 | 1,180 | --- | --- | Add to Cart |

| FX-8113 |  |

75-85D | Amber | 100:99 | 10-15 | 1,400 | 270,000 | 1.1 | Add to Cart |

| FX-8258 |  |

75-85D | White | 100:50 | 5:30 - 8:30 | 1,000 | 300,000 | 0.7 | |

| FX-8300 |  |

75-85D | Off White | 100:87 | 6-8 | 450 | 386,190 | 1.6 | |

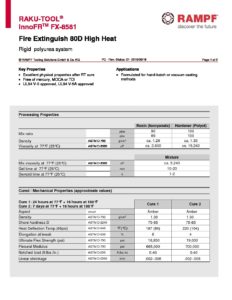

| FX-8575 |  |

77-87D | Clear | 100:63 | 10-20 | 175 | 350,000 | 0.8 | Add to Cart |

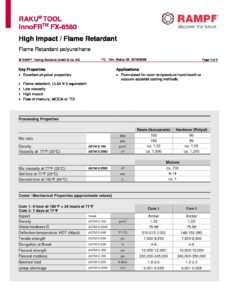

| FX-8580 |  |

75-85D | Amber | 100:60 | 8-14 | 700 | 230,000-245,000 | 1.8 - 2.3 | |

| FX-8581 |  |

75-85D | Amber | 90:100 | 5:30 - 8:30 | 2,600 | 665,000 | 0.4 | Add to Cart |

| FX-8585-1 |  |

80-90D | White | 100:56 | 5:30 - 8:30 | 1,550 | 265,000 | 0.8 | Add to Cart |

| FX-8587 |  |

75-80D | Clear | 100:43.5 | 20-25 | 2,200 | 342.500 | 1.1 | |

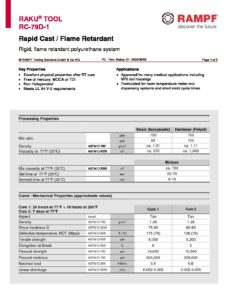

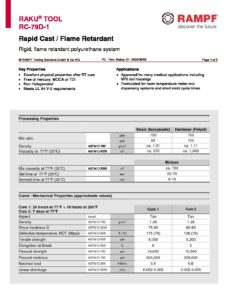

| RC-79D-1 |  |

75-85D | Tan | 100:100 | 50-75 sec | 700 | 300,000 | 0.6 | Add to Cart |

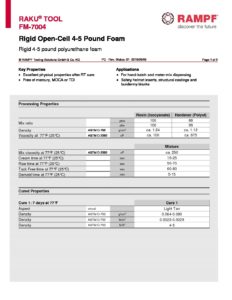

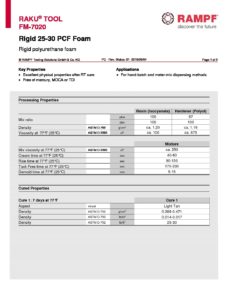

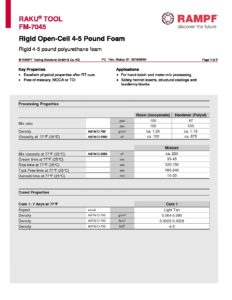

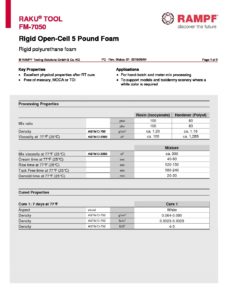

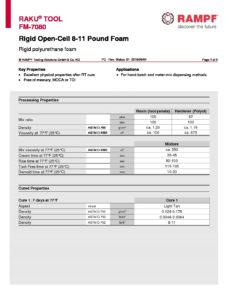

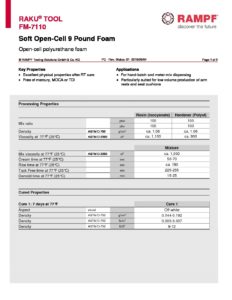

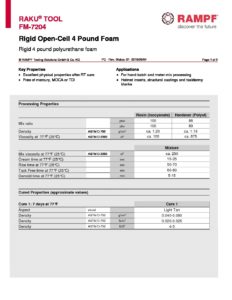

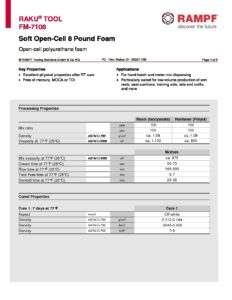

FM Series liquid urethanes create quick demoldable foams with options for different hardness and densities.

All FM Series foams are machine dispensable. Other options include cartridge dispensing and hand pouring depending on the foam formulation.

The applications for FM Series urethane foams include the following: automotive components; military training aids; prototypes; sports and recreation equipment; taxidermy cores; amusement parks; themed environments; architectural models.

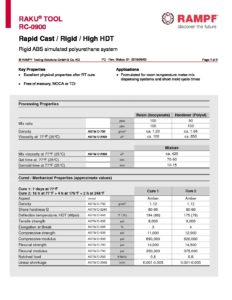

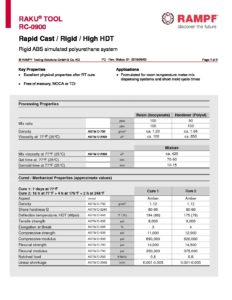

Need polyurethanes with quick demold times? The fast curing urethane liquid plastics in the RapidCast™ series are designed to be used with meter-mix dispensing into molds built from a variety of tooling materials. Several of the systems are also suitable for cartridge dispensing. RapidCast™ Shore D hardness polyurethanes are typically used for producing functional ABS- and polypropylene-like prototype parts. The product line includes UL 94 V-O flame retardant materials a FDA-compliant (CFR 21.177.1680) product for dry food contact and a room-temperature cure, high-heat material for under-hood automotive prototypes.

RapidCast™ polyurethanes can be demolded after 5 to 30 minutes at room temperature and feature excellent flexural modulus and great elevated temperature performance

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time sec | Mix Viscosity cps | Flex Mod psi | Notched Izod ft-lb/in | Add to Cart |

|---|---|---|---|---|---|---|---|---|---|

| RC-79D-1 |  |

75-85D | Tan | 100:100 | 50-75 | 700 | 300,000 | 0.6 | Add to Cart |

| RC-0082 |  |

75-85D | Translucent | 100:86 | 40-60 | 375 | 285,000 | 0.7 | Add to Cart |

| RC-0200 |  |

75-85D | Off-White | 100:89 | 50-70 | 900 | 175,000 | 3.0 | |

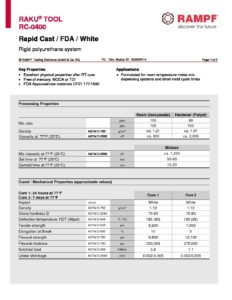

| RC-0400 |  |

75-85D | White | 100:88 | 50-60 | 1,200 | 275,000 | 1.1 | |

| RC-0510 |  |

80-90D | Black | 100:90 | 40-60 | 700 | 350,000 | 0.5 | Add to Cart |

| RC-0555 |  |

75-85D | Black | 100:88 | 60-80 | 500 | 210,000 | 1.1 | Add to Cart |

| RC-0900 |  |

80-90D | Amber | 100:90 | 70-90 | 425 | 350,000 | 0.8 | Add to Cart |

Continue Reading

Talk to the team

Have questions about a product? Want something custom made just for you?

Get in touch with one of our expert sales-representatives for more information about our products.