Our castable polyurethane systems are formulated to meet demanding casting, coating, and foam applications. With ASTM and UL flame‑rated options, clear systems, and 2‑part expandable foams, these materials offer versatility for molding, roto‑casting, hard coating, and sprayable applications. Produced with state‑of‑the‑art processing and verified through rigorous quality control, RAMPF polyurethanes deliver consistent performance for a wide range of production needs.

Your Benefits:

– Cutting edge, high performance castable polyurethane systems

– Available in ASTM or UL flame rated materials

– Versatile application methods

– Excellent uniformity and consistency

– Each batch undergoes rigorous quality control testing before shipment

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time min | Viscosity cP | Flex Mod psi | Notched Izod ft-lb/in | |

|---|---|---|---|---|---|---|---|---|---|

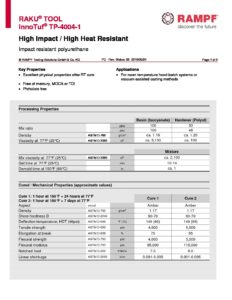

| TP-4004-1 |  |

60-70D | Amber | 100:50 | 10-14 | 2,100 | 115,000 | 6.0 | View Product |

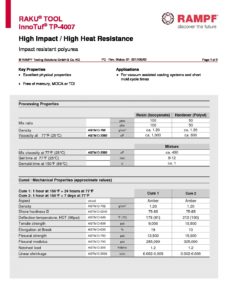

| TP-4007 |  |

75-85D | Amber | 100:50 | 8-12 | 400 | 325,000 | 1.2 | View Product |

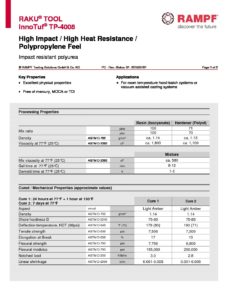

| TP-4008 |  |

75-85D | Light Amber | 100:71 | 8-12 | 580 | 200,000 | 2.8 | View Product |

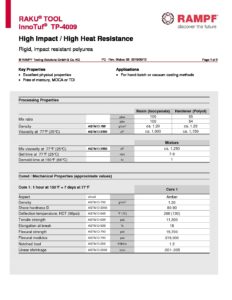

| TP-4009 |  |

80-90D | Amber | 100:55 | 7-9 | 1,275 | 316,000 | 1.2 | View Product |

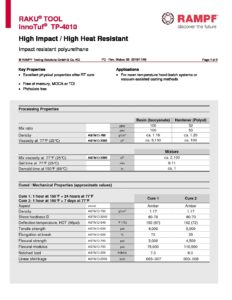

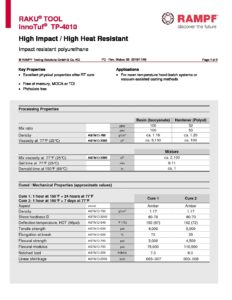

| TP-4010 |  |

60-70D | Amber | 100:52 | 8-11 | 2,100 | 110,500 | 6.0 | View Product |

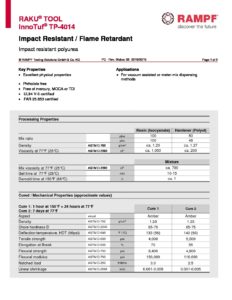

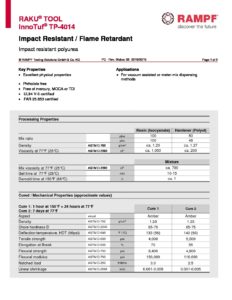

| TP-4014 |  |

65-75D | Amber | 100:48 | 10-15 | 1,050 | 150,000 | 3.0 | View Product |

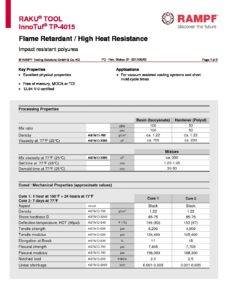

| TP-4015 |  |

65-75D | Black | 100:50 | 1:25 - 1:35 | 350 | 168,300 | 2.5 | View Product |

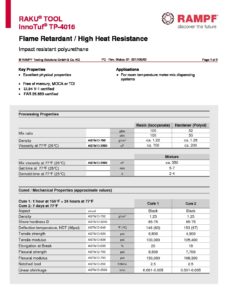

| TP-4016 |  |

65-75D | Black | 100:52 | 5-7 | 350 | 168,300 | 2.5 | View Product |

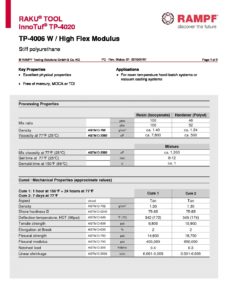

| TP-4020 |  |

75-85D | Tan | 100:46 | 8-12 | 1,300 | 650,000 | 0.3 | View Product |

| TP-4040 |  |

65-75D | Black | 100:53 | 1:30 - 2:30 | 2,100 | 110,000 | 6.5 | View Product |

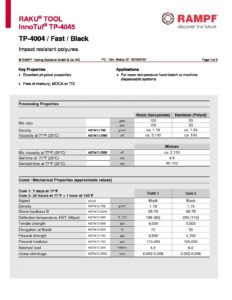

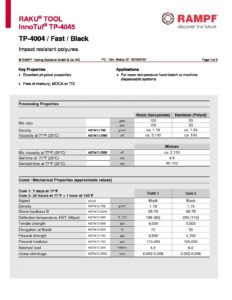

| TP-4045 |  |

65-75D | Black | 100:53 | 4-6 | 2,100 | 110,000 | 6.5 | View Product |

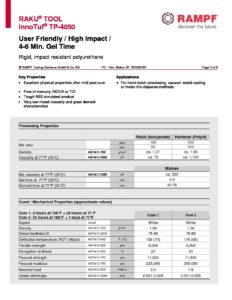

| TP-4050 |  |

75-85D | White | 100:100 | 4-6 | 325 | 250,000 | 1.8 | View Product |

| TP-4052 |  |

75-85D | White | 100:50 | 5-9 | 600 | 250,000 | 1.7 | View Product |

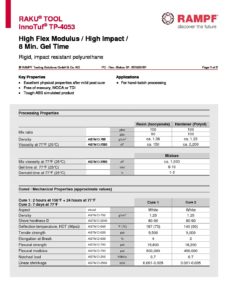

| TP-4053 |  |

80-90D | White | 100:100 | 6-10 | 1,000 | 450,000 | 0.7 | View Product |

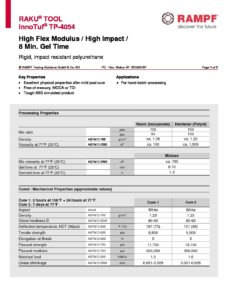

| TP-4054 |  |

80-90D | White | 100:100 | 6-10 | 700 | 350,000 | 1.0 | View Product |

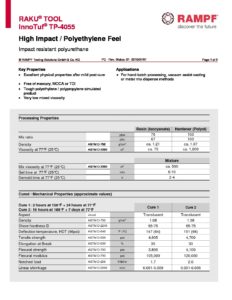

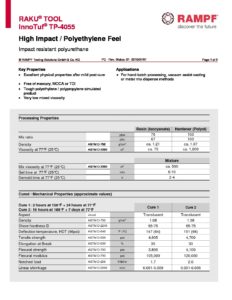

| TP-4055 |  |

65-75D | Translucent | 76:100 | 6-10 | 500 | 120,000 | 2.0 | View Product |

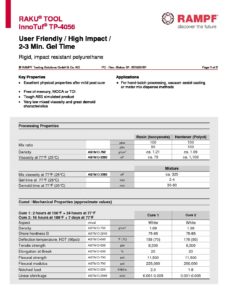

| TP-4056 |  |

75-85D | White | 100:100 | 2-4 | 325 | 250,000 | 1.8 | View Product |

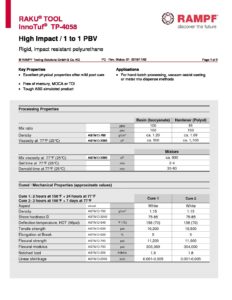

| TP-4058 |  |

75-85D | White | 100:91 | 2-4 | 900 | 304,000 | 1.8 | View Product |

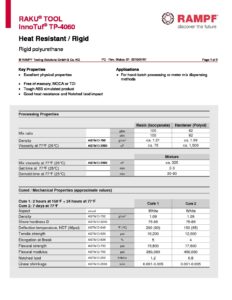

| TP-4060 |  |

75-85D | White | 100:82 | 2-3 | 325 | 450,000 | 0.8 | View Product |

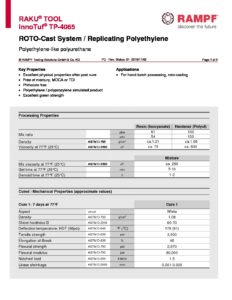

| TP-4065 |  |

60-70D | White | 61:100 | 7-10 | 250 | 80,000 | 1.5 | View Product |

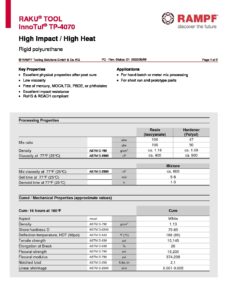

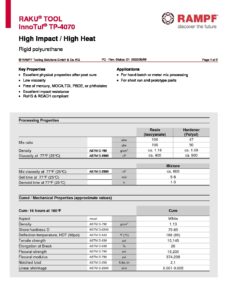

| TP-4070 |  |

75-85D | White | 100:47 | 5-8 | 600 | 374,238 | 2.1 | View Product |

| TP-4071 |  |

75-85D | White | 100:47 | 10-14 | 600 | 374,238 | 2.1 | View Product |

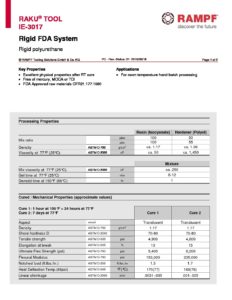

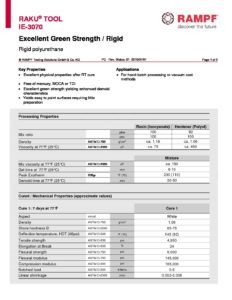

| IE-3017 FDA Approved |  |

70-80D | White | 100:55 | 8-12 | 250 | 235,000 | 1.7 | View Product |

| IE-3025 |  |

65-75D | Translucent | 100:94 | 2:30-3:30 | 100 | 200,000 | 0.6 | View Product |

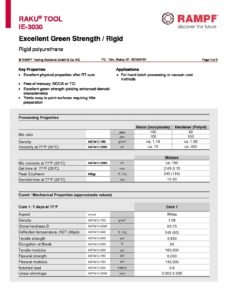

| IE-3030 |  |

65-75D | White | 100:92 | 2:45-3:15 | 150 | 145,000 | 0.6 | View Product |

| IE-3065 |  |

65-75D | Light Gray | 100:97 | 4-8 | thixotropic | 635,000 | 0.6 | View Product |

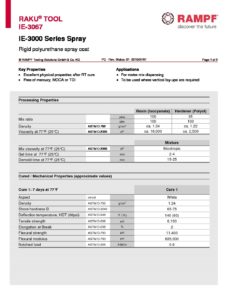

| IE-3067 |  |

65-75D | White | 100:91 | 2-4 | thixotropic | 635,000 | 0.6 | View Product |

| IE-3070 |  |

65-75D | White | 100:92 | 6-10 | 150 | 145,000 | 0.6 | View Product |

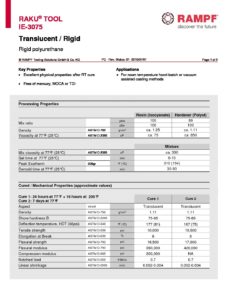

| IE-3075 |  |

75-85D | Translucent | 100:89 | 6-10 | 300 | 420,000 | 0.7 | View Product |

| IE-3077 |  |

70-80D | Translucent | 100:94 | 4-6 | 100 | 267,000 | 0.6 | View Product |

| IE-3092 |  |

70-80D | Translucent | 100:100 | 8-12 | 250 | 250,000 | 0.8 | View Product |

| IE-3092-1 |  |

70-80D | Translucent | 100:90 | 6-8 | 150 | 250.000 | 0.80 | View Product |

| IE-3461 |  |

55-65D | Beige | 100:98 | 4-6 | 2,500 | 175,000 | 0.80 | View Product |

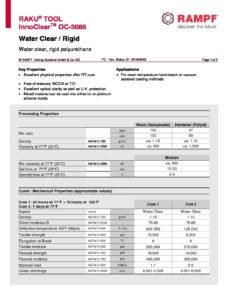

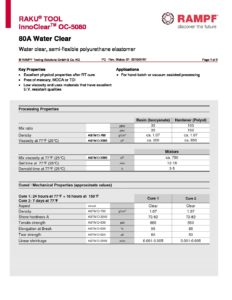

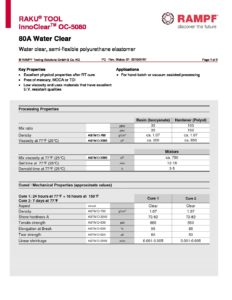

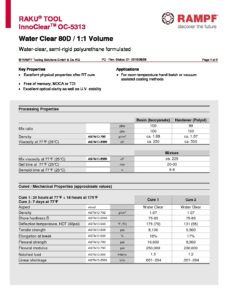

| OC-5085 |  |

75-85D | Water Clear | 100:57 | 80-120 | 650 | 350,000 | 0.3 | View Product |

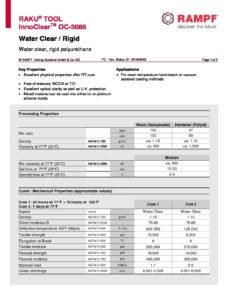

| OC-5086 |  |

75-85D | Clear | 100:57 | 15-20 | 450 | 345,000 | 1.1 | View Product |

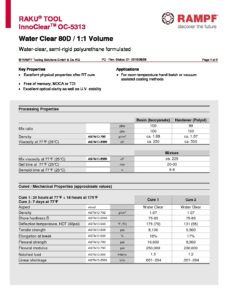

| OC-5313 |  |

75-85D | Water Clear | 100:100 | 20-30 | 225 | 250,000 | 1.5 | View Product |

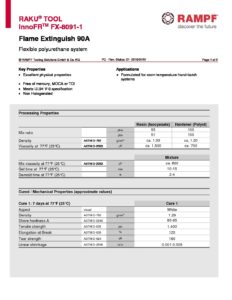

| FX-8113 |  |

75-85D | Amber | 100:100 | 8-12 | 550 | 270,000 | 1.1 | View Product |

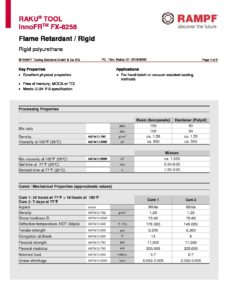

| FX-8258-1 |  |

75-85D | White | 100:50 | 5:30-8:30 | 1,500 | 300,000 | 0.7 | View Product |

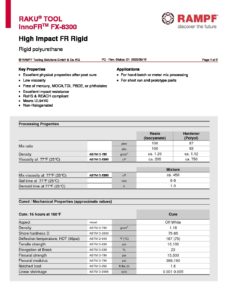

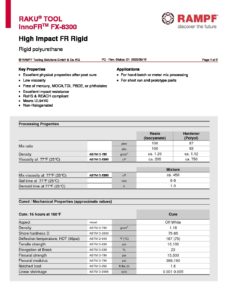

| FX-8300 |  |

75-85D | Off White | 100:87 | 6-8 | 450 | 386,190 | 1.6 | View Product |

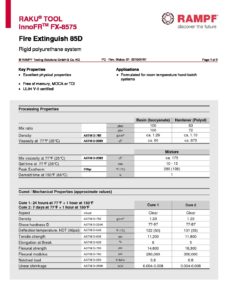

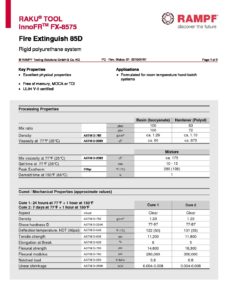

| FX-8575 |  |

77-87D | Clear | 100:63 | 10-15 | 175 | 350,000 | 0.8 | View Product |

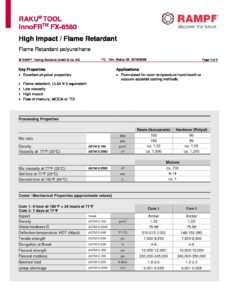

| FX-8580 |  |

75-85D | Amber | 100:60 | 8-14 | 700 | 250,000 | 1.8 | View Product |

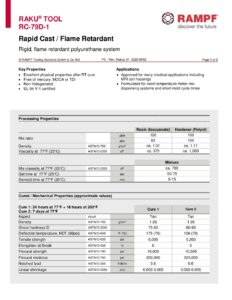

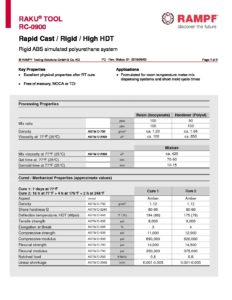

| RC-79D-1 |  |

80-90D | Tan | 100:100 | 50-75 sec | 700 | 325,000 | 0.6 | View Product |

| RC-0082 |  |

75-85D | Translucent | 100:86 | 40-60 sec | 375 | 285,000 | 0.7 | View Product |

| RC-0200 |  |

75-85D | Off-White | 100:89 | 50-70 sec | 900 | 175,000 | 3.0 | View Product |

| RC-0510 |  |

80-90D | Black | 100:90 | 40-60 sec | 700 | 350,000 | 0.5 | View Product |

| RC-0555 |  |

75-85D | Black | 100:88 | 60-80 sec | 500 | 210,000 | 1.1 | View Product |

| RC-0900 |  |

80-90D | Amber | 100:90 | 70-90 sec | 425 | 350,000 | 0.8 | View Product |

RAMPF’s semi‑rigid polyurethane systems—spanning the HP, TP, and IE Series—feature low‑viscosity, easy‑processing formulations with excellent elongation, tear strength, and durable mechanical performance. These materials offer strong flexural and tensile properties, high impact strength, and reliable heat and chemical resistance across the full semi‑rigid range.

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time min | Viscosity cps | Tear Strength pli | Notched Izod ft-lb/in | |

|---|---|---|---|---|---|---|---|---|---|

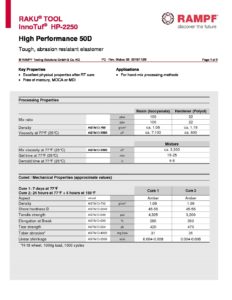

| HP-2250 |  |

45-55D | Amber | 100:22 | 15-25 | 3,300 | 420 | --- | View Product |

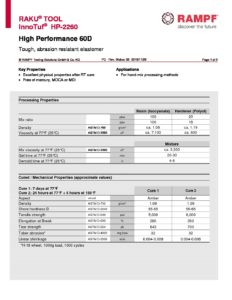

| HP-2260 |  |

55-65D | Amber | 100:20 | 20-30 | 3,300 | 643 | --- | View Product |

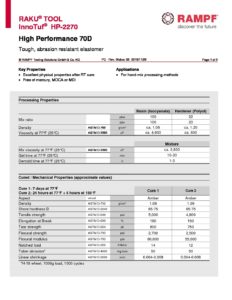

| HP-2270 |  |

65-75D | Amber | 100:22 | 10-20 | 3,800 | 800 | 14.0 | View Product |

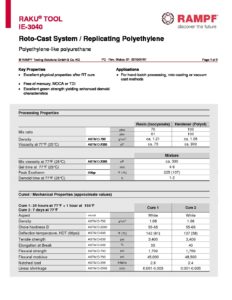

| IE-3040 |  |

55-65D | White | 70:100 | 4-6 | 300 | --- | 2.4 | View Product |

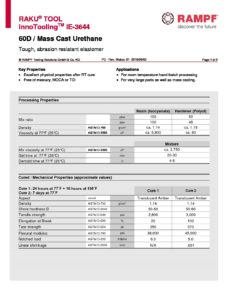

| IE-3644-1 |  |

50-60D | Translucent Amber | 100:50 | 20-30 | 2,750 | 350 | --- | View Product |

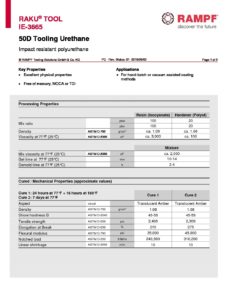

| IE-3665 |  |

45-55D | Translucent Amber | 100:20 | 10-14 | 2,200 | --- | 10 | View Product |

| TP-4004-1 |  |

60-70D | Amber | 100:50 | 10-14 | 2,100 | --- | 7.0 | View Product |

| TP-4010 |  |

60-70D | Amber | 100:52 | 8-11 | 2,100 | --- | 7.0 | View Product |

| TP-4014 |  |

65-75D | Amber | 100:50 | 10-15 | 700 | --- | 3.0 | View Product |

| TP-4045 |  |

65-75D | Black | 100:53 | 4-6 | 2,100 | --- | 6.5 | View Product |

| TP-4055 |  |

65-75D | Translucent | 76:100 | 6-10 | 500 | --- | 1.7 | View Product |

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time min | Viscosity cps | Tear Strength pli | Tensile Strength psi | |

|---|---|---|---|---|---|---|---|---|---|

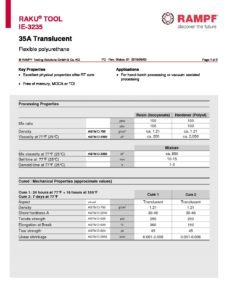

| IE-3235 |  |

30-40A | Translucent | 100:100 | 10-15 | 850 | 45 | 200 | View Product |

| IE-3240 |  |

32-42A | Off-White | 100:95 | 20-30 | 950 | 75 | 900 | View Product |

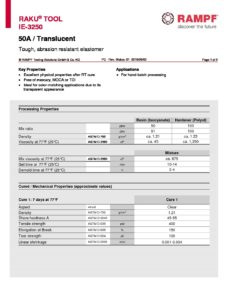

| IE-3250 |  |

45-55A | Clear | 50:100 | 10-14 | 875 | 100 | 400 | View Product |

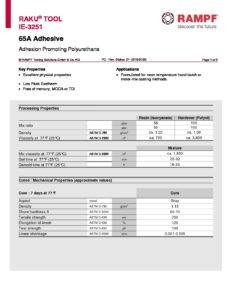

| IE-3251 |  |

60-70A | Gray | 56:100 | 22-32 | 1,950 | 105 | 700 | View Product |

| IE-3252 |  |

45-55A | Off-White | 40:100 | 20-30 | 800 | 120 | 900 | View Product |

| IE-3253 |  |

60-70A | Translucent | 100:92 | 7-10 | 1,300 | 150 | 1100 | View Product |

| IE-3254 |  |

45-55A | Bronze | 61:100 | 10-15 | 875 | 100 | 400 | View Product |

| IE-3257 |  |

45-55A | White | 16:100 | 9-15 | 775 | 25 | 200 | View Product |

| IE-3260 |  |

50-60A | Cream | 25:100 | 7-13 | 975 | 100 | 800 | View Product |

| IE-3261 |  |

55-65A | Clear | 50:100 | 9-15 | 575 | 75 | 500 | View Product |

| IE-3262 |  |

55-65A | Tan | 50:100 | 9-15 | 575 | 110 | 550 | View Product |

| IE-3270 |  |

65-75A | Cream | 34:100 | 7-13 | 975 | 180 | 1,700 | View Product |

| IE-3273 |  |

65-75A | White | 30:100 | 7-13 | 775 | 45 | 500 | View Product |

| IE-3275 |  |

70-80A | White | 95:100 | 30-60 | 675 | 80 | 800 | View Product |

| IE-3280 |  |

75-85A | Cream | 35:100 | 7-13 | 975 | 180 | 1,700 | View Product |

| IE-3285 |  |

75-85A | Black | 100:13 | 20-30 | 3,100 | 200 | 1,300 | View Product |

| IE-3288 |  |

75-85A | White | 37:100 | 7-13 | 775 | 110 | 1,000 | View Product |

| IE-3290 |  |

80-90A | Cream | 38:100 | 7-13 | 975 | 215 | 1,750 | View Product |

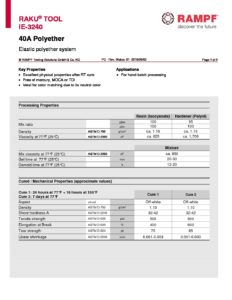

| IE-3500 |  |

35-45A | Light Amber | 60:100 | 16-20 | 2,000 | 75 | 450 | View Product |

| IE-3600 |  |

55-65A | Light Amber | 60:100 | 16-20 | 2,000 | 65 | 450 | View Product |

| IE-3700 |  |

65-75A | Cream | 59:100 | 16-20 | 2,000 | 125 | 800 | View Product |

| IE-3800 |  |

75-85A | Cream | 35:100 | 16-20 | 2,000 | 230 | 1,170 | View Product |

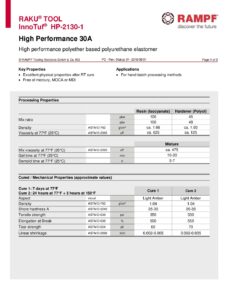

| HP-2130-1 |  |

25-35A | Light Amber | 100:45 | 10-20 | 475 | --- | 350 | View Product |

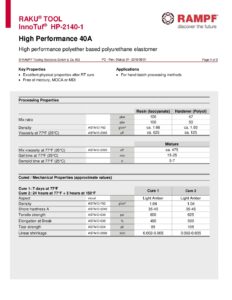

| HP-2140-1 |  |

35-45A | Light Amber | 100:47 | 15-25 | 475 | --- | 600 | View Product |

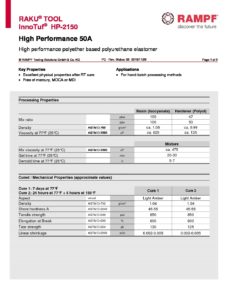

| HP-2150 |  |

45-55A | Light Amber | 100:47 | 20-3 | 475 | --- | 850 | View Product |

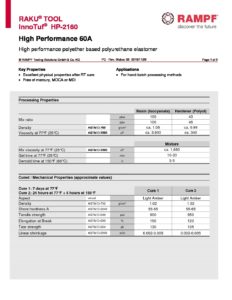

| HP-2160 |  |

55-65A | Light Amber | 100:43 | 10-20 | 1,660 | --- | 900 | View Product |

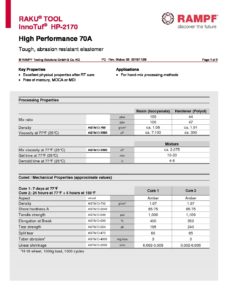

| HP-2170 |  |

65-75A | Amber | 100:44 | 10-20 | 2,075 | --- | 1,000 | View Product |

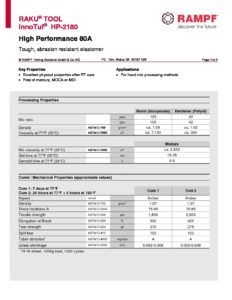

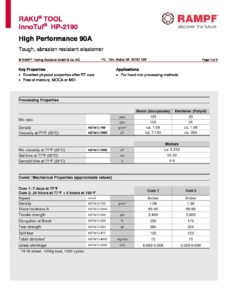

| HP-2180 |  |

75-85A | Amber | 100:40 | 15-25 | 2,800 | --- | 1,800 | View Product |

| HP-2190 |  |

85-95A | Amber | 100:30 | 20-30 | 3,300 | --- | 3,400 | View Product |

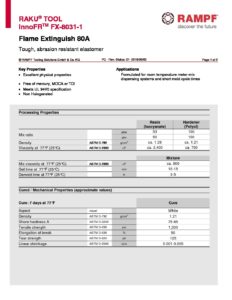

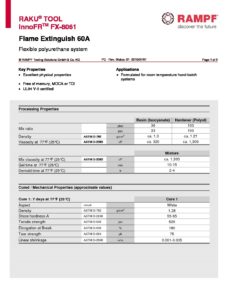

| FX-8031-1 |  |

75-85A | White | 53:100 | 25-35 | 800 | 125 | 1,200 | View Product |

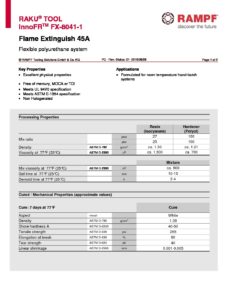

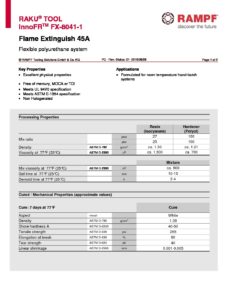

| FX-8041-1 |  |

40-50A | White | 27:100 | 10-15 | 800 | 40 | 255 | View Product |

| FX-8061-1 |  |

55-65A | White | 36:100 | 10-15 | 800 | 75 | 525 | View Product |

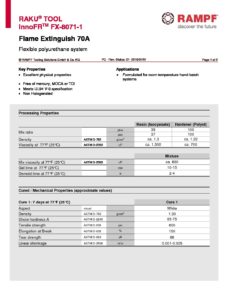

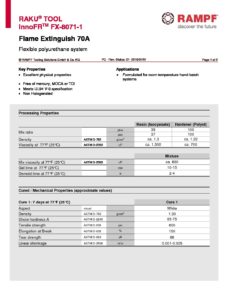

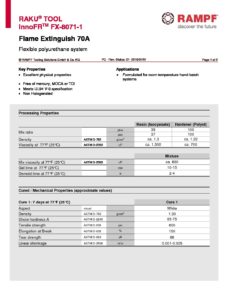

| FX-8071-1 |  |

65-75A | White | 39:100 | 10-15 | 1,850 | 86 | 600 | View Product |

| FX-8081-1 |  |

75-85A | White | 44:100 | 10-15 | 800 | 135 | 1,050 | View Product |

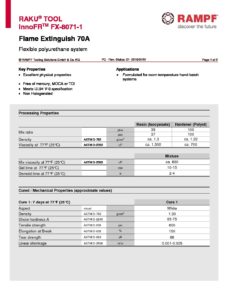

| FX-8091-1 |  |

85-95A | White | 55:100 | 10-15 | 800 | 160 | 1,400 | View Product |

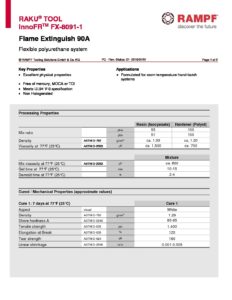

| FX-8258 |  |

75-85D | White | 100:50 | 5:30 - 8:30 | 1,000 | ___ | 6,200 | View Product |

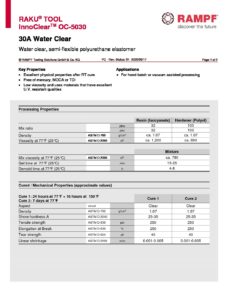

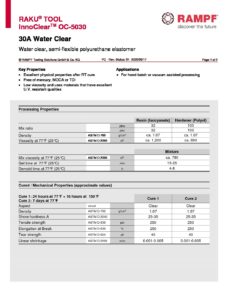

| OC-5030 |  |

25-35A | Clear | 32:100 | 15-25 | 1,200 | --- | 250 | View Product |

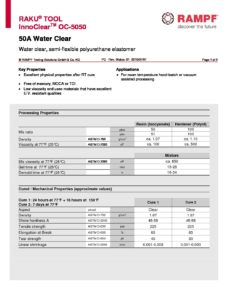

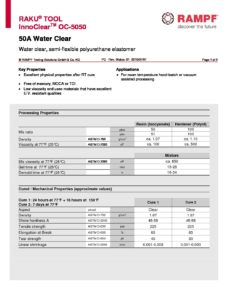

| OC-5050 |  |

45-55A | Clear | 50:100 | 15-25 | 650 | --- | 225 | View Product |

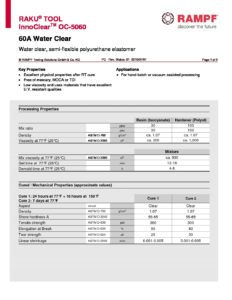

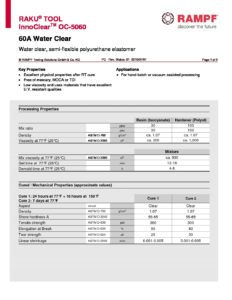

| OC-5060 |  |

55-65A | Clear | 30:100 | 12-18 | 900 | --- | 300 | View Product |

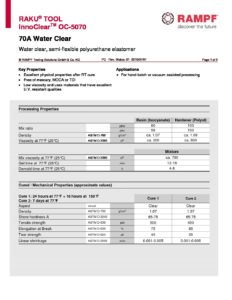

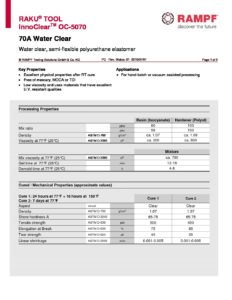

| OC-5070 |  |

65-75A | Clear | 60:100 | 12-18 | 700 | --- | 450 | View Product |

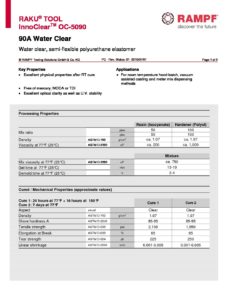

| OC-5080 |  |

72-82A | Clear | 35:100 | 12-18 | 750 | --- | 550 | View Product |

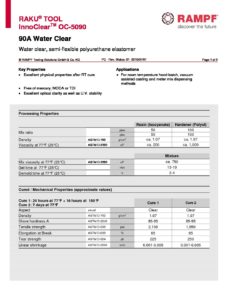

| OC-5090 |  |

85-95A | Clear | 50:100 | 13-19 | 750 | 250 | 1,950 | View Product |

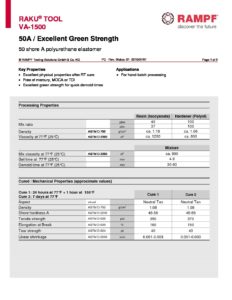

| VA-1500 |  |

45-55A | Neutral Tan | 40:100 | 4-6 | 900 | 40 | 370 | View Product |

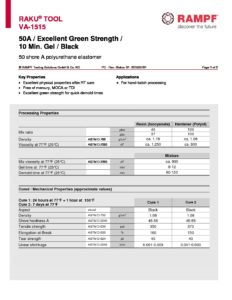

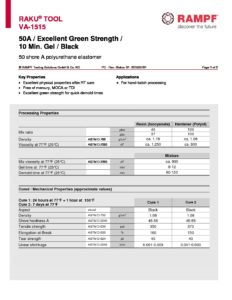

| VA-1515 |  |

45-55A | Black | 40:100 | 8-12 | 900 | 40 | 350 | View Product |

| VA-1600 |  |

55-65A | Neutral Tan | 52:100 | 3-5 | 850 | 40 | 325 | View Product |

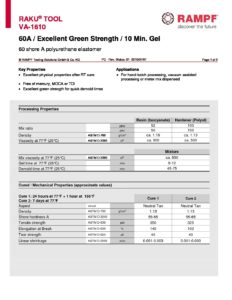

| VA-1610 |  |

55-65A | Neutral Tan | 52:100 | 8-12 | 850 | 40 | 350 | View Product |

| VA-1615 |  |

55-65A | Black | 52:100 | 8-12 | 850 | 40 | 350 | View Product |

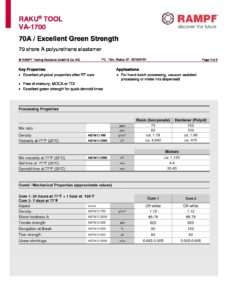

| VA-1700 |  |

65-75A | Off-White | 70:100 | 4-6 | 1,110 | 60 | 635 | View Product |

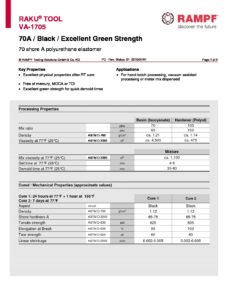

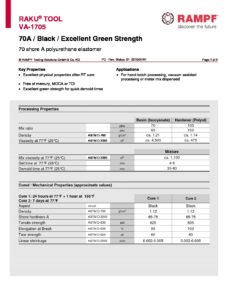

| VA-1705 |  |

65-75A | Black | 70:100 | 4-6 | 1,110 | 60 | 620 | View Product |

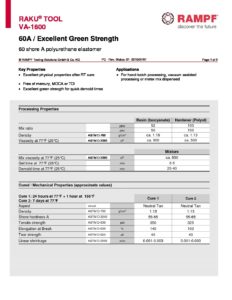

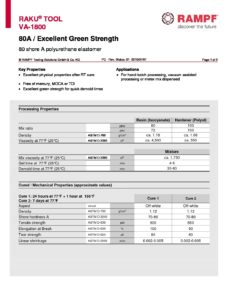

| VA-1800 |  |

70-80A | Off-White | 80:100 | 4-6 | 1,750 | 60 | 650 | View Product |

| VA-1805 |  |

70-80A | Black | 80:100 | 4-6 | 1,750 | 80 | 900 | View Product |

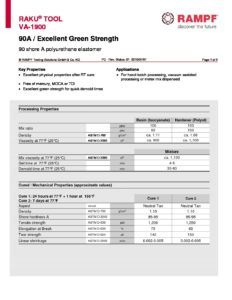

| VA-1900 |  |

85-95A | Neutral Tan | 100:100 | 4-6 | 1,100 | 130 | 1,250 | View Product |

| VA-1915 |  |

85-95A | Black | 100:100 | 8-12 | 1,100 | 140 | 1,200 | View Product |

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time min | Viscosity cps | Flex Mod. psi | Notched Izod ft-lb/in | |

|---|---|---|---|---|---|---|---|---|---|

| OC-5030 |  |

25-35A | Clear | 32:100 | 15-25 | 790 | --- | --- | View Product |

| OC-5050 |  |

45-55A | Clear | 50:100 | 15-25 | 650 | --- | --- | View Product |

| OC-5060 |  |

55-65A | Clear | 30:100 | 12-18 | 900 | --- | --- | View Product |

| OC-5070 |  |

65-75A | Clear | 600:100 | 12-18 | 700 | --- | --- | View Product |

| OC-5080 |  |

72-82A | Clear | 35:100 | 12-18 | 750 | --- | --- | View Product |

| OC-5085 |  |

75-85D | Water Clear | 100:57 | 80-100 | 650 | 350,000 | 0.3 | View Product |

| OC-5086 |  |

75-85D | Water Clear | 100:57 | 15-20 | 650 | 350,000 | 0.5 | View Product |

| OC-5090 |  |

85-95A | Clear | 50:100 | 13-19 | 750 | --- | --- | View Product |

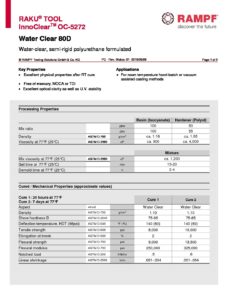

| OC-5272 |  |

75-85D | Water Clear | 100:50 | 15-20 | 1,200 | 325,000 | 0.6 | View Product |

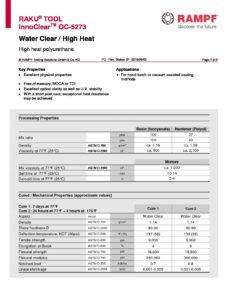

| OC-5273 |  |

80-90D | Water Clear | 100:37 | 10-14 | 1,000 | 350,000 | 0.7 | View Product |

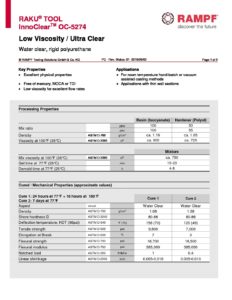

| OC-5274 |  |

80-86D | Water Clear | 100:50 | 15-23 | 750 | 385,000 | 0.4 | View Product |

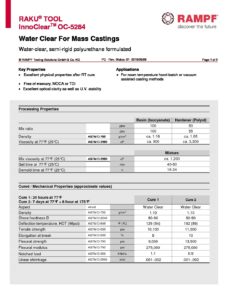

| OC-5284 |  |

80-90D | Water Clear | 100:50 | 40-60 | 1,200 | 275,000 | 1.1 | View Product |

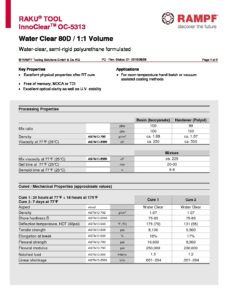

| OC-5313 |  |

75-85D | Water Clear | 100:92 | 20-30 | 225 | 250,000 | 1.5 | View Product |

| OC-5320 |  |

75-85D | Water Clear | 100:62 | 30-40 | 650 | 345,000 | 1.0 | View Product |

| OC-5436 |  |

80-85D | Transparent | 100:56 | 18-22 | 730 | 390,000 | 1.0 | View Product |

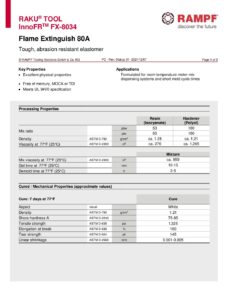

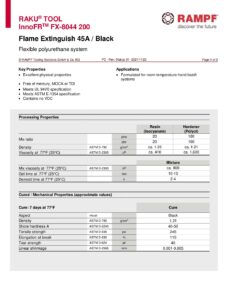

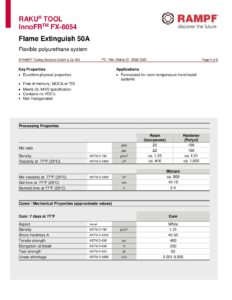

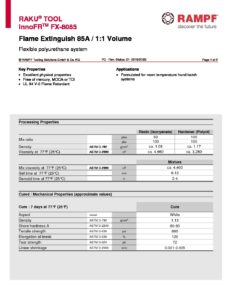

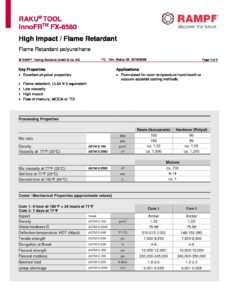

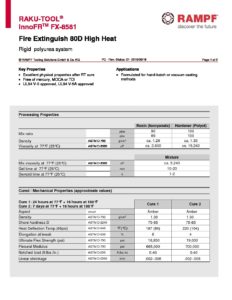

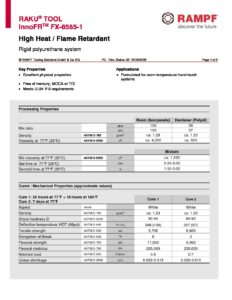

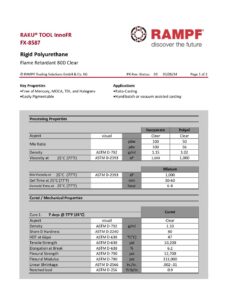

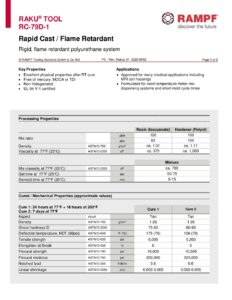

RAMPF’s flame‑retardant polyurethane materials meet UL94 V‑0 and additional flame‑test standards, while providing strong flexural characteristics, high heat resistance, and reliable mechanical performance.

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time min | Viscosity cps | Flex Mod. psi | Notched Izod ft-lb/in | |

|---|---|---|---|---|---|---|---|---|---|

| FX-8034 |  |

75-85A | White | 53:100 | 10-15 | 850 | - | - | View Product |

| FX-8044 |  |

40-50A | Black | 20:100 | 10-15 | 900 | - | - | View Product |

| FX-8054 |  |

45-55A | White | 22:100 | 10-15 | 900 | - | - | View Product |

| FX-8064 |  |

55-65A | Grey/Blue | 30:100 | 10-15 | 915 | --- | --- | View Product |

| FX-8071-1 |  |

65-75A | White | 39:100 | 10-15 | 1,850 | --- | --- | View Product |

| FX-8081-1 |  |

75-85A | White | 44:100 | 10-15 | 1,850 | --- | --- | View Product |

| FX-8085 |  |

80-90A | White | 100:100 | 8-12 | 4,400 | --- | --- | View Product |

| FX-8091-1 |  |

85-95A | White | 55:100 | 8-12 | 1,180 | --- | --- | View Product |

| FX-8113 |  |

75-85D | Amber | 100:99 | 10-15 | 1,400 | 270,000 | 1.1 | View Product |

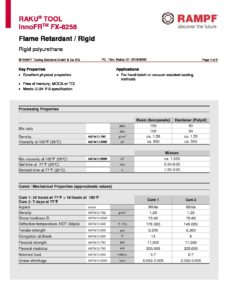

| FX-8258-1 |  |

75-85D | White | 100:50 | 5:30 - 8:30 | 1,000 | 300,000 | 0.7 | View Product |

| FX-8300 |  |

75-85D | Off White | 100:87 | 6-8 | 450 | 386,190 | 1.6 | View Product |

| FX-8575 |  |

77-87D | Clear | 100:63 | 10-20 | 175 | 350,000 | 0.8 | View Product |

| FX-8580 |  |

75-85D | Amber | 100:60 | 8-14 | 700 | 230,000-245,000 | 1.8 - 2.3 | View Product |

| FX-8581 |  |

75-85D | Amber | 90:100 | 5:30 - 8:30 | 2,600 | 665,000 | 0.4 | View Product |

| FX-8585-1 |  |

80-90D | White | 100:56 | 5:30 - 8:30 | 1,550 | 265,000 | 0.8 | View Product |

| FX-8587 |  |

75-80D | Clear | 100:50 | 30-40 | 1,000 | 313,000 | 0.9 | View Product |

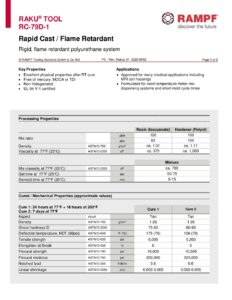

| RC-79D-1 |  |

75-85D | Tan | 100:100 | 50-75 sec | 700 | 300,000 | 0.6 | View Product |

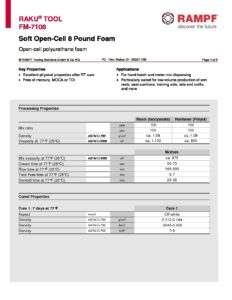

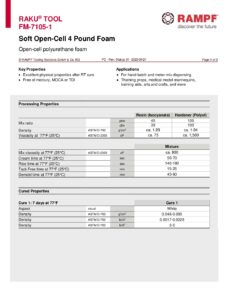

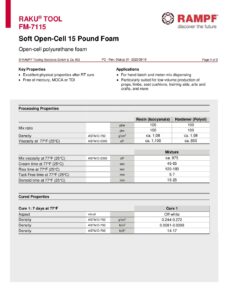

| Product | Datasheet | Color | Density g/cm³ | Density lb/ft³ | Mix Ratio pbw | Mix Viscosity cP | Demold Time min | |

|---|---|---|---|---|---|---|---|---|

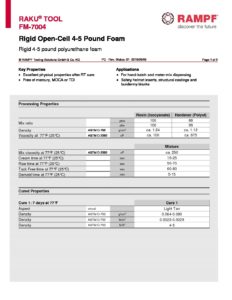

| FM-7004 |  |

Light Tan | 0.064-0.080 | 4-5 | 100:88 | 250 | 5-15 | View Product |

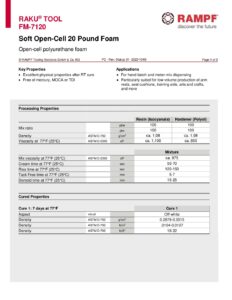

| FM-7120 |  |

Off White | 0.288-0.351 | 18-22 | 100:100 | 975 | 15-25 | View Product |

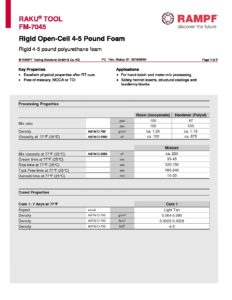

| FM-7045 |  |

Light Tan | 0.064-0.080 | 4-5 | 100:97 | 250 | 10-20 | View Product |

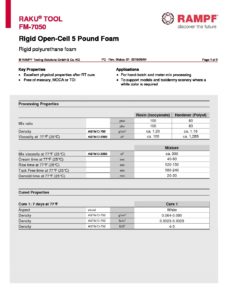

| FM-7050 |  |

White | 0.064-0.080 | 4-5 | 100:80 | 300 | 20-30 | View Product |

| FM-7080 |  |

Light Tan | 0.128-0.176 | 8-11 | 100:97 | 250 | 10-20 | View Product |

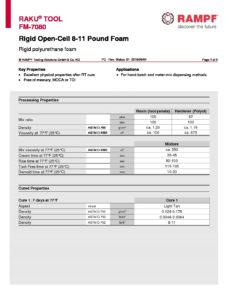

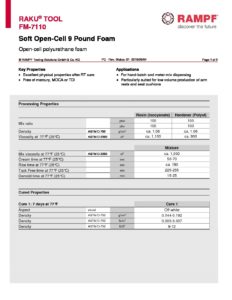

| FM-7110 |  |

Off-White | 0.144-0.192 | 9-12 | 100:100 | 1,000 | 15-25 | View Product |

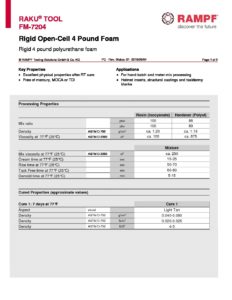

| FM-7204 |  |

Light Tan | 0.040-0.080 | 4-5 | 100:88 | 250 | 5-15 | View Product |

| FM-7108 |  |

Off-white | 0.112-0.144 | .0045-0.005 | 100:100 | 975 | 25-35 | View Product |

| FM-7105-1 |  |

White | 0.048-0.080 | 3-5 | 45:100 | 800 | 45-60 | View Product |

| FM-7115 |  |

Off White | 0.244-0.272 | 14-17 | 100:100 | 975 | 15-25 | View Product |

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time sec | Mix Viscosity cps | Flex Mod psi | Notched Izod ft-lb/in | |

|---|---|---|---|---|---|---|---|---|---|

| RC-79D-1 |  |

75-85D | Tan | 100:100 | 50-75 | 700 | 300,000 | 0.6 | View Product |

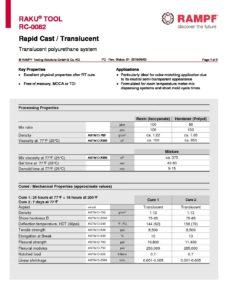

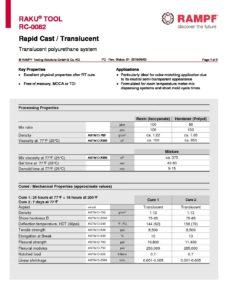

| RC-0082 |  |

75-85D | Translucent | 100:86 | 40-60 | 375 | 285,000 | 0.7 | View Product |

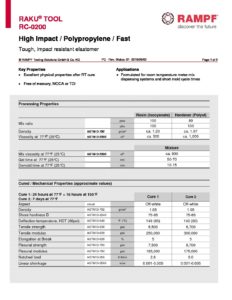

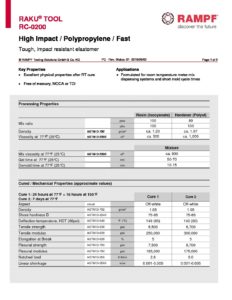

| RC-0200 |  |

75-85D | Off-White | 100:89 | 50-70 | 900 | 175,000 | 3.0 | View Product |

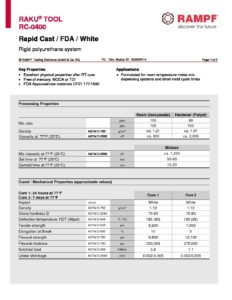

| RC-0400 |  |

75-85D | White | 100:88 | 50-60 | 1,200 | 275,000 | 1.1 | View Product |

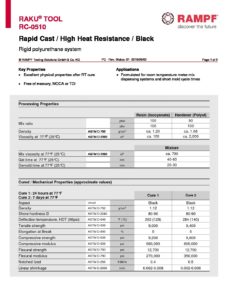

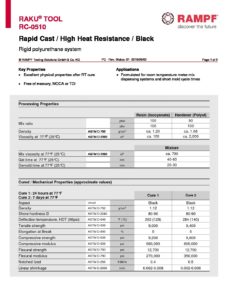

| RC-0510 |  |

80-90D | Black | 100:90 | 40-60 | 700 | 350,000 | 0.5 | View Product |

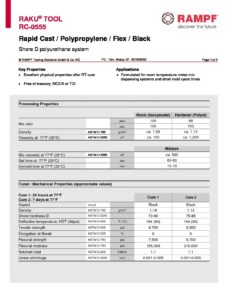

| RC-0555 |  |

75-85D | Black | 100:88 | 60-80 | 500 | 210,000 | 1.1 | View Product |

| RC-0900 |  |

80-90D | Amber | 100:90 | 70-90 | 425 | 350,000 | 0.8 | View Product |

Have questions about a product? Want something custom made just for you?

Get in touch with one of our expert sales-representatives for more information about our products.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |