RAMPF’s silicones are engineered for creating durable molds that deliver accurate prototypes and detailed reproductions across a wide range of applications. With low to no shrinkage and outstanding replication of fine details, these addition‑cure and condensation‑cure silicones are available in multiple hardnesses to meet diverse project requirements. Paired with versatile silicone options designed for mold making, props, and creative fabrication, RAMPF silicones support precision, customization, and exceptional mold performance.

Your Benefits:

– Low to no shrinkage, ensuring accurate, reliable prototype and mold dimensions

– Outstanding replication of fine details, ideal for precise mold making

– Available in multiple cure types (addition and condensation cure) to match project needs

– Offered in several hardness options, giving flexibility for a wide variety of applications

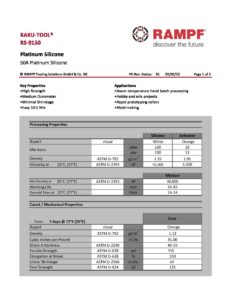

Platinum‑cured silicones offer high tear strength, low viscosity, and minimal shrinkage, with a room‑temperature 10:1 mix that processes easily and cures with excellent dimensional stability.

| Product | Datasheet | Hardness | Mixed Viscosity | Tensile Strength | Tear Strength | Elongation | |

|---|---|---|---|---|---|---|---|

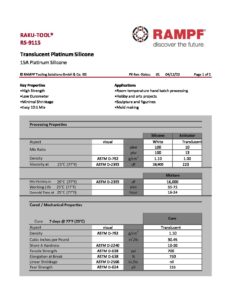

| RS-9115 |  |

10-20A | 16,000 cP | 700 psi | 155 pli | 750% | View Product |

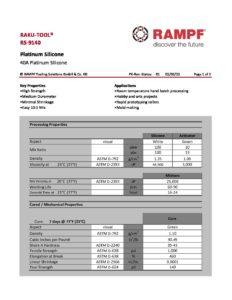

| RS-9140 |  |

35-45A | 25,000 cP | 1,000 psi | 140 pli | 460% | View Product |

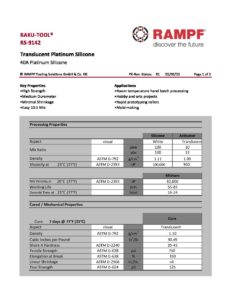

| RS-9142 |  |

35-45A | 82,000 cP | 750 psi | 125 pli | 350% | View Product |

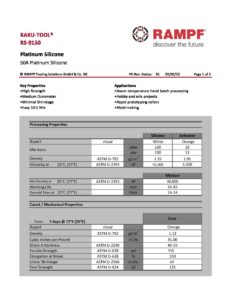

| RS-9150 |  |

45-55A | 30,000 cP | 715 psi | 125 pli | 150% | View Product |

| RS-9160 |  |

55-65A | 28,000 cP | 900 psi | 140 pli | 135% | View Product |

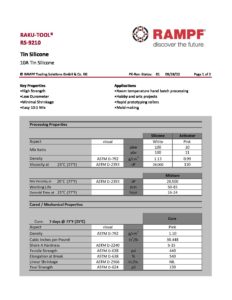

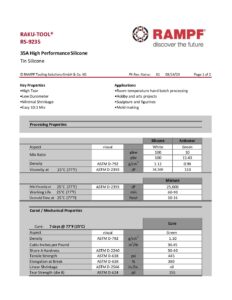

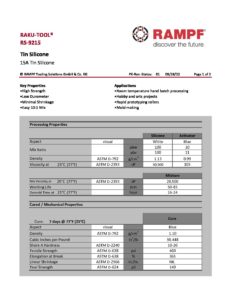

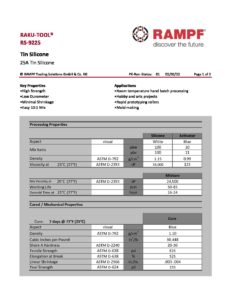

Tin‑cured silicones provide dependable tear strength, low viscosity, and minimal shrinkage, featuring a simple 10:1 room‑temperature mix for smooth, consistent processing

| Product | Datasheet | Hardness | Mixed Viscosity | Tensile Strength | Tear Strength | Elongation | |

|---|---|---|---|---|---|---|---|

| RS-9210 |  |

5-15A | 20,500 cP | 440 psi | 130 pli | 540% | View Product |

| RS-9235 |  |

30-40A | 25,000 cP | 445 psi | 155 pli | 380% | View Product |

| RS-9215 |  |

10-20A | 20,500 cP | 460 psi | 140 pli | 365% | View Product |

| RS-9225 |  |

20-30A | 24,500 cP | 615 psi | 155 pli | 525% | View Product |

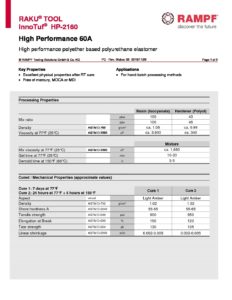

| Product | Datasheet | Hardness | Color | Mix Ratio pbw | Gel Time min | Viscosity cps | Tear Strength pli | Notched Izod ft-lb/in | |

|---|---|---|---|---|---|---|---|---|---|

| HP-2160 |  |

55-65A | Light Amber | 100:43 | 10-20 | 1,660 | --- | 900 | View Product |

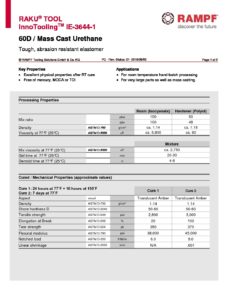

| IE-3644-1 |  |

50-60D | Translucent Amber | 100:50 | 20-30 | 2,750 | 350 | 6.0 | View Product |

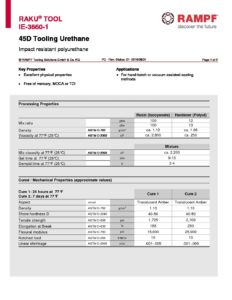

| IE-3660-1 |  |

40-50D | Translucent Amber | 100:12 | 9-13 | 2,200 | --- | 10 | View Product |

COMING SOON

Have questions about a product? Want something custom made just for you?

Get in touch with one of our expert sales-representatives for more information about our products.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |